A Guide to Sprayed Edges Book Printing for Self-Publishers

A Guide to Sprayed Edges Book Printing for Self-Publishers

In the ever-evolving world of self-publishing, authors are constantly looking for unique ways to make their books stand out. One technique that is getting a lot of attention is sprayed edge printing. This innovative binding method not only enhances the beauty of a book, but also provides a tactile experience that readers cherish. In this guide, we'll explore what sprayed edges is, the printing techniques involved, the benefits of using sprayed edges, and tips for self-publishers looking to incorporate this feature into their projects.

1. What are Sprayed Edges?

Sprayed Edges refers to a finishing technique commonly used in graphic design and digital art, in which paint or graphics are sprayed on the edges of surfaces to produce a specific aesthetic effect. This technique can be used in both physical and digital media to achieve different cosmetic effects such as soft gradients, blended colors, or textured looks.

2. Printing Techniques

There are various methods used to create sprayed edges, including:

Spraying by Hand: This manual technique involves applying a spray paint to the edges after the book block has been assembled. It allows for creative freedom, enabling unique designs or color blends.

Automated Spraying Systems: High-quality and consistent results can be achieved using automated systems that spray edge colors onto books during the binding process.

Digital Printing: Some printers can incorporate sprayed edges directly into the digital printing process, allowing for precise and customizable options.

3. Benefits of Using Sprayed Edges

Using sprayed edges in design and art offers several benefits that enhance both aesthetic appeal and functionality. Here are some of the key advantages:

Enhanced Aesthetics

Soft Transition: Sprayed edges create smooth transitions between colors, which can soften the overall look of a design or artwork.

Dynamic Texture: This technique adds texture and depth, making designs feel more three-dimensional and visually interesting.

Versatility

Wide Range of Applications: Sprayed edges can be used in various media, from graphic design and illustration to traditional painting and digital art.

Adaptability: This technique can fit into numerous styles, including street art, abstract, and even subtle branding designs.

Creative Expression

Unique Effects: Artists and designers can use sprayed edges to create one-of-a-kind effects that stand out and enhance their visual storytelling.

Personal Touch: The organic nature of sprayed edges often results in unpredictable patterns, allowing for a more spontaneous and personal artistic expression.

Depth and Dimension

Visual Interest: By adding depth, sprayed edges can draw the viewer’s eye, creating focal points and guiding them through the artwork.

Layering: This technique can be layered with other design elements, enriching the overall composition.

Branding and Identity

Consistent Theme: Using sprayed edges can help establish a specific visual identity for brands, making their materials more recognizable and memorable.

Emotional Connection: The casual and artistic feel can evoke certain emotions, making designs more relatable and engaging.

Ease of Use

Accessibility: With available digital tools, creating sprayed effects has become straightforward, allowing even those with limited skills to achieve impressive results.

Time-Saving: Sprayed edges can quickly transform a flat design into something more complex and appealing without extensive labor.

Cohesion in Composition

Framing and Boundaries: Sprayed edges can create natural boundaries that delineate different elements of a design, helping to structure and unify the overall layout.

Blending Elements: They can smoothly integrate different graphic elements, making designs feel more cohesive.

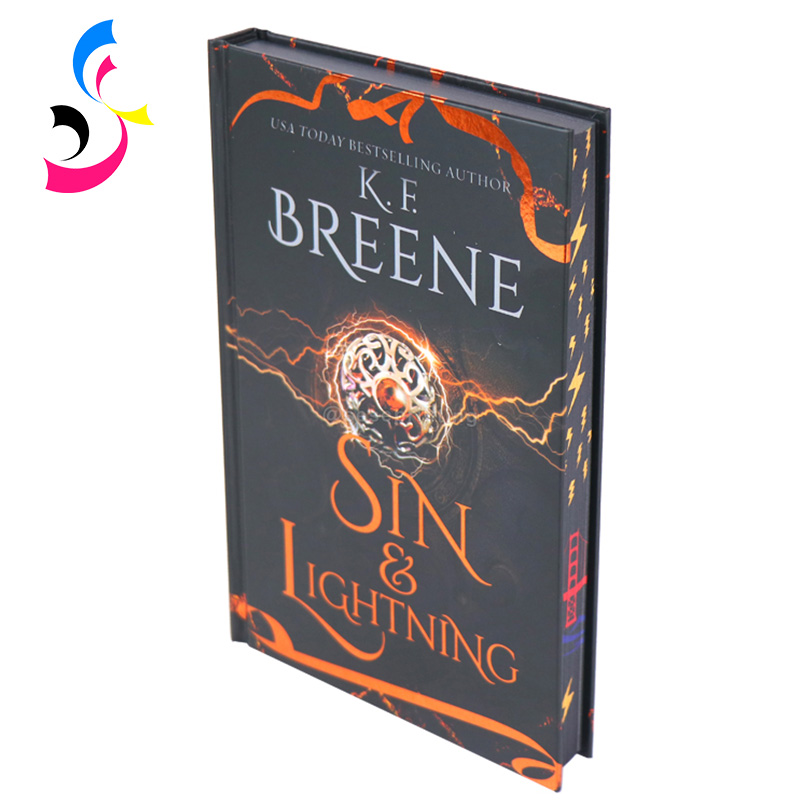

4. Selecting the Right Books (Hardcover vs. Paperback)

Hardcover Books:

◪ Durability: Hardcovers are more resistant to wear and tear, making them ideal for long-term collections.

◪ Aesthetic Appeal: Edge-painted hardcovers often look more visually striking and can elevate the overall presentation of a book.

◪ Better Support for Reading: The sturdy binding provides better support, making it comfortable to read without damaging the spine.

◪ Cost: Hardcovers typically cost more than paperbacks, which might be a deterrent for some readers.

◪ Weight: They are heavier and less portable, which can be an issue for readers who travel or commute frequently.

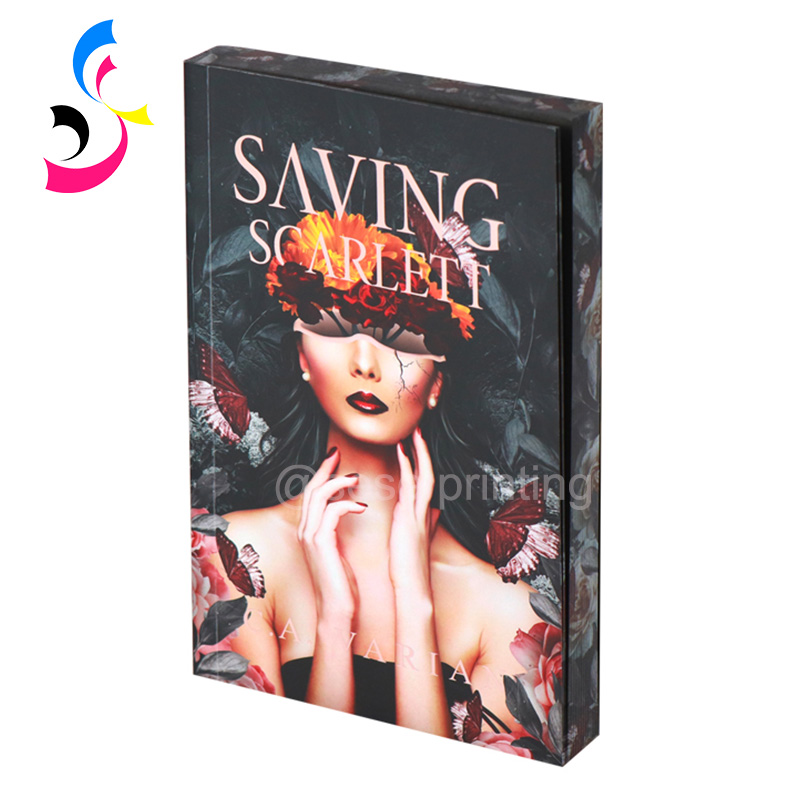

Paperback Books:

◪ Affordability: Paperbacks are generally less expensive, making them an attractive option for casual readers or those on a budget.

◪ Lightweight and Portable: They are easier to carry around, perfect for reading on the go.

◪ Variety: Often, more titles are available in paperback than in hardcover, especially for new releases.

◪ Durability Issues: Paperbacks may not withstand wear as well and can be prone to bending or tearing, particularly at the spine.

◪ Less Visual Impact: Edge painting is less common in paperbacks, which might make them less visually appealing for collectors.

5. Step-by-Step Process for Sprayed Edges Book Printing

Pre-Press Preparation

File Preparation: Ensure the book’s design files are formatted correctly (PDF, high-resolution images, etc.).

Proofing: Create a proof copy to check for any errors in layout, text, and design before proceeding.

Printing

Ink Selection: Choose water-based or special inks that are appropriate for the book's purpose and desired finish.

Printing Method: Use offset printing or digital printing, depending on the quantity and budget.

Paper Selection: Select high-quality paper that will hold the sprayed edge finishing well.

Binding

Gathering: Assemble the printed sheets into pages (signatures).

Collating: Arrange the pages in the correct order.

Binding Process: Use methods such as perfect binding, case binding, or saddle stitching, depending on the book type.

Trimming

Trimming the Edges: Use a guillotine cutter to trim the book’s edges to the final size, leaving a clean finish.

Edge Spraying

Setup Spraying Machine: Prepare the edge-spraying machine, ensuring it is calibrated for even coverage.

Masking: Use masking tape to protect the covers from overspray. Ensure the book is securely positioned.

Spray Application: Apply the desired color or finish to the edges using the spraying machine. Choices often include:

Solid color sprays

Gradients or patterns

Metallic or glitter finishes

Drying: Allow the sprayed edges to dry completely. This may involve air drying or passing through a drying unit.

Quality Control

Inspection: Check the sprayed edges for consistency, coverage, and any defects.

Touch-Up as Needed: Perform any necessary touch-ups on the edges or binding.

Packaging

Wrapping: Package the finished books carefully to protect them during shipping or storage. This may involve shrink-wrapping or boxing.

Labeling: Affix labels on boxes for easy inventory management and identification.

6. Common Challenges and Solutions

Inconsistent Color Application: This can be remedied through careful technique and practice, or by opting for automated spraying.

Drying Time: Ensure adequate drying time to prevent smudging, especially when using hand spraying techniques.

Limited Options for Paperbacks: Research printers that offer competitive solutions for paperback formats to ensure quality.

7. Production Costs and Pricing

The cost of implementing sprayed edges can vary widely based on the selected technique, the size of the book, and the number of copies printed. While automated methods may increase initial costs, they can lead to economies of scale in larger print runs. Self-publishers should factor in these costs into their pricing strategy while maintaining competitive rates in the market.

8. Market Trends and Reader Preferences

Recent market studies indicate a rising trend in the preference for unique book finishes among readers, particularly in the young adult and fantasy genres. Sprayed edges have emerged as a popular finishing touch that can enhance the visual appeal of a book, appealing to collectors and casual readers alike.

9. Maintenance and Care

Books with sprayed edges should be handled carefully to avoid damage. It’s advisable to store them upright in a cool, dry place, away from direct sunlight, to ensure the edges retain their color and integrity. Regular dusting will help maintain the appearance of both the book and its sprayed edges.

Conclusion

At SESE Printing, we believe that every book has the potential to stand out and make a memorable impact on readers. Our expertise in sprayed edges printing allows self-publishers to elevate their works with visually stunning finishes that capture attention and spark interest. With our state-of-the-art techniques and commitment to quality, we help authors not just produce books, but craft beautiful artifacts that resonate with audiences.

As the publishing landscape evolves, innovative features like sprayed edges are essential for self-publishers who want to leave a lasting impression. Let us partner with you to transform your vision into reality and create books that not only tell stories but also captivate and inspire. Choose SESE Printing for your next project, and watch as your work becomes a masterpiece that stands out on the shelves. Contact us today to learn more about how we can help you shine!

E-mail: sales01@seseprinting.com

Mobile phone: +86-13570912663

WhatsApp: 008613501482344

Tel: +86-020-34613569

Add: 702 No. 21 Huizhong Road, Shiqiao St, Panyu District. Guangzhou city, Guangdong Province. China