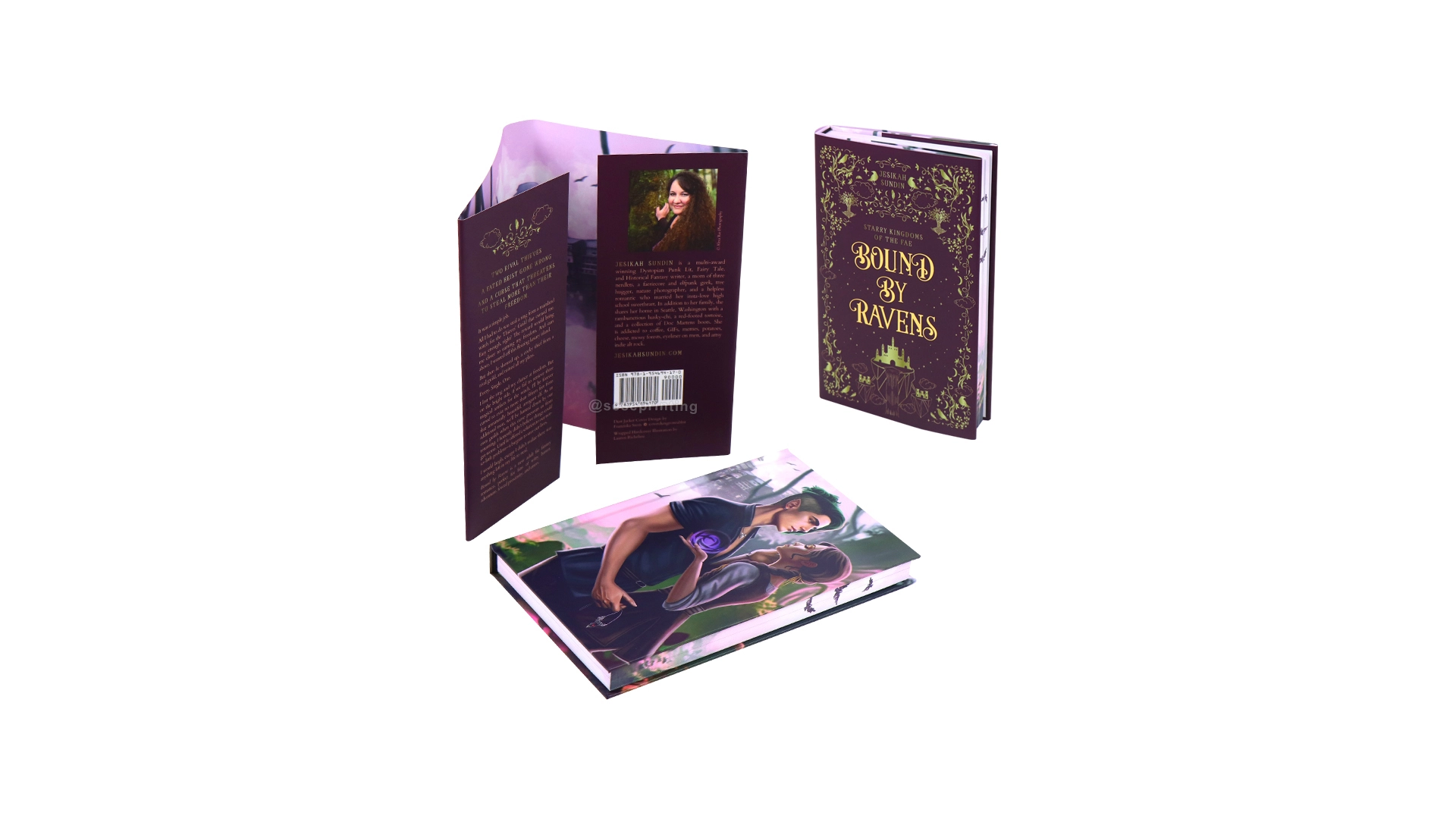

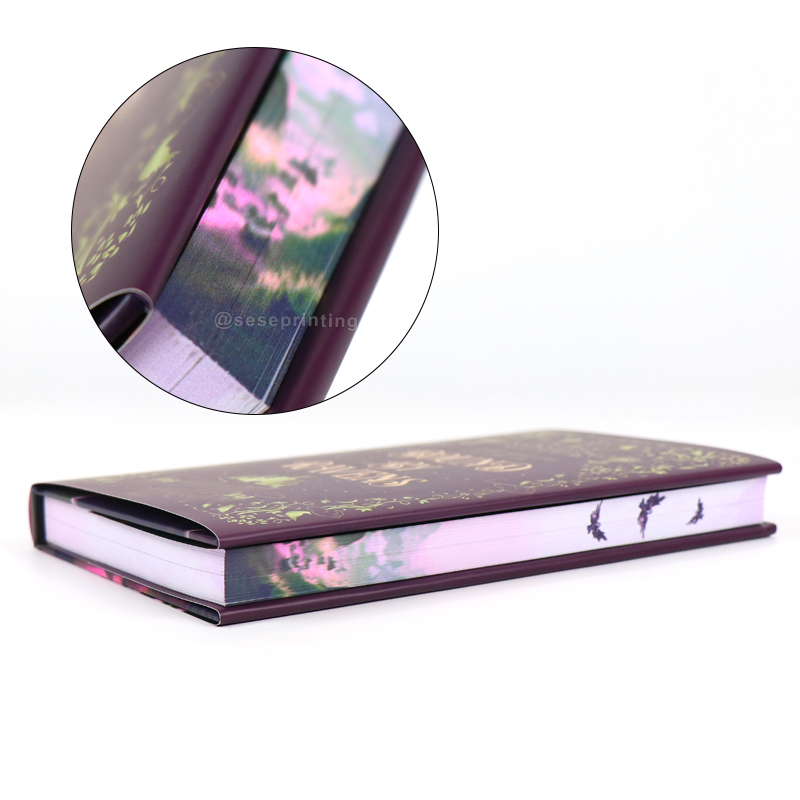

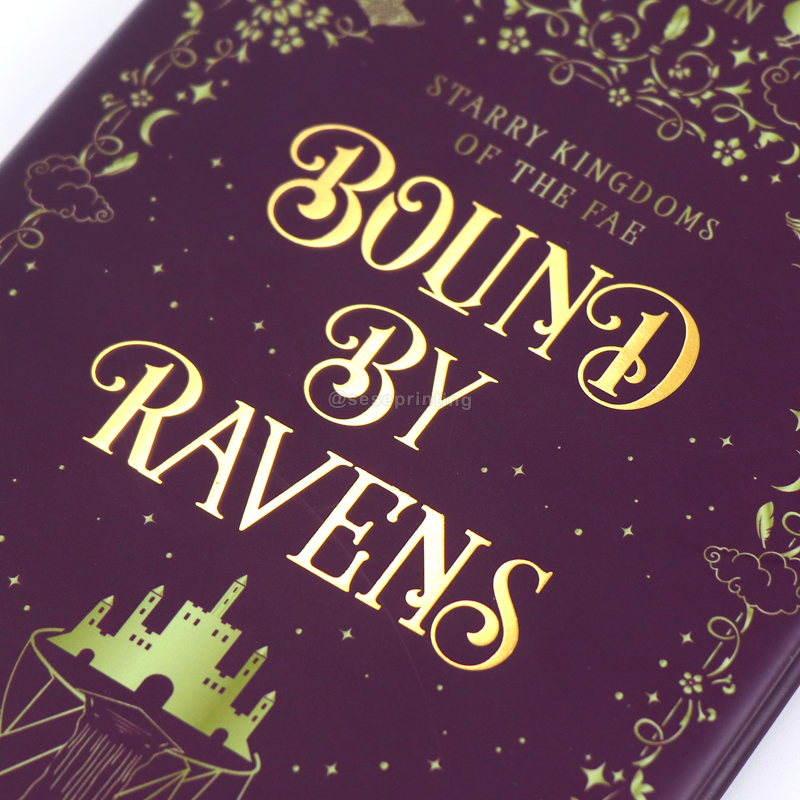

Luxury Sprayed Book Edges Hardcover Book Printing Manufacturer

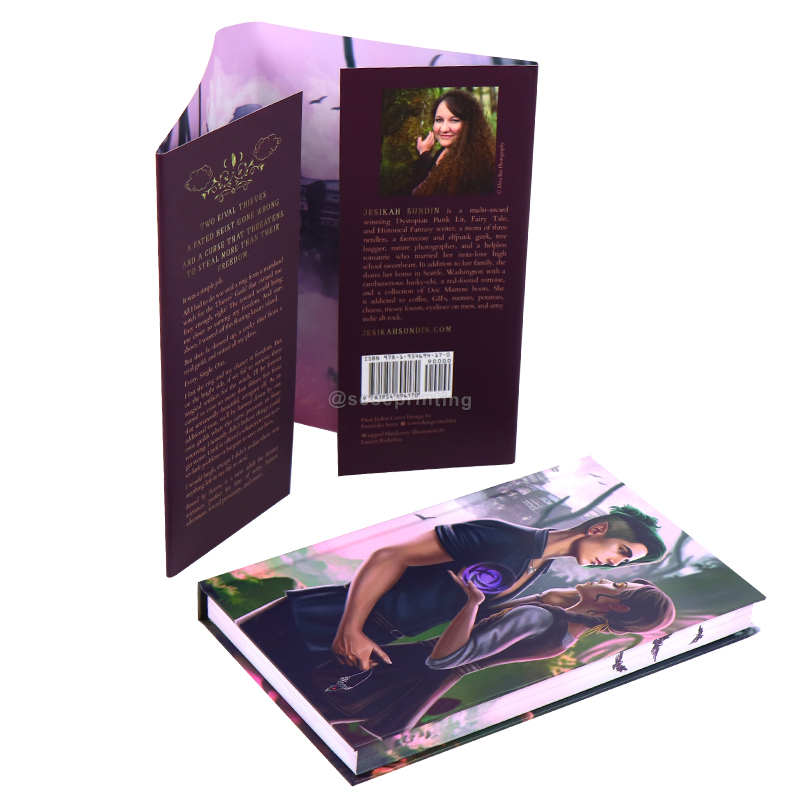

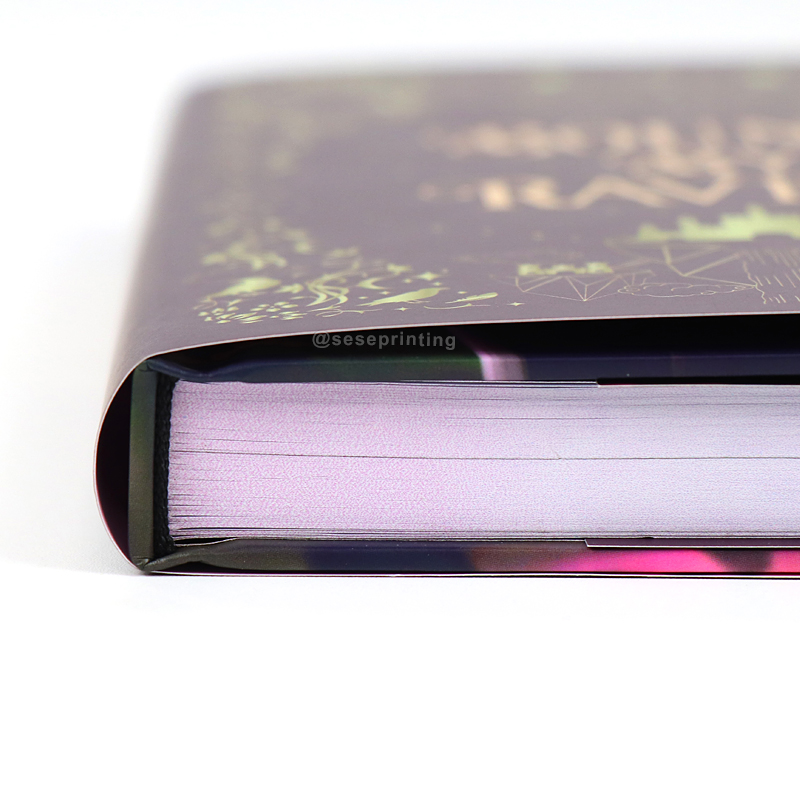

Our precision spraying technique ensures a seamless and luxurious touch, adding a tactile and visual allure to your literary masterpiece. Enhance the overall aesthetic and prestige of your book collection with our premium sprayed edges printing.

Luxury Sprayed Book Edges Hardcover Book Printing Manufacturer

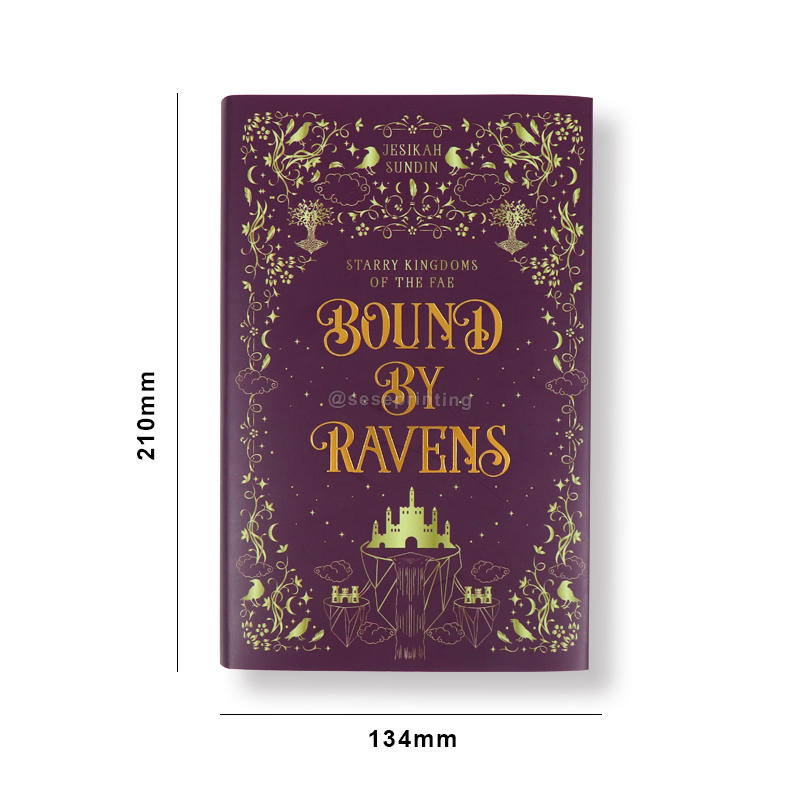

| Product Name | Sprayed Edges Book | |||

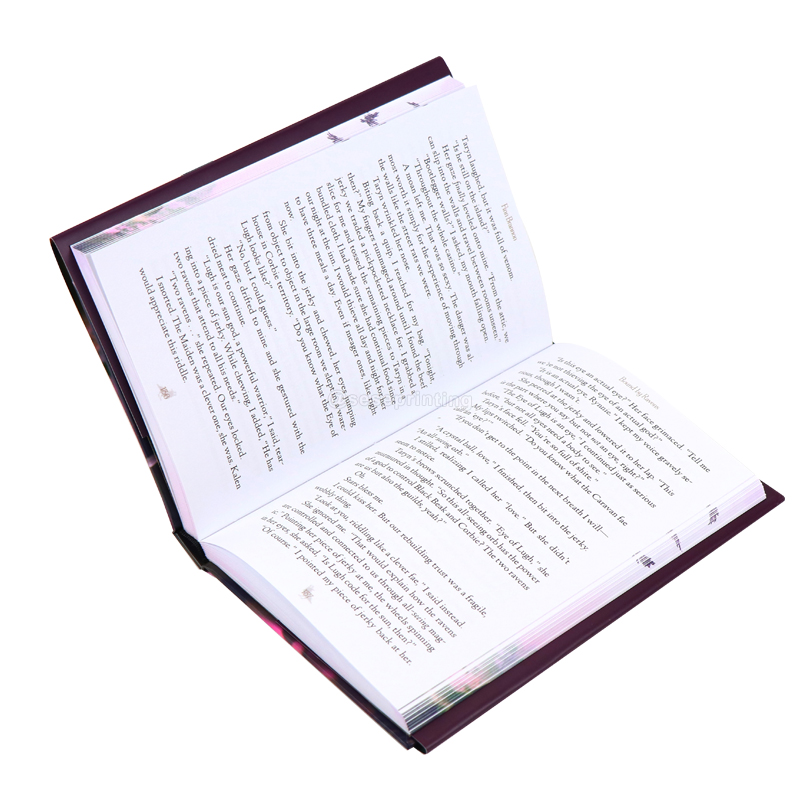

| Material | Glossy/matt art paper, offset paper, woodfree paper, writing paper, light coated paper, special type paper, C1S C2S board,C1S grey board, kraft paper, light weight coated paper, wood free paper, and so on. | |||

| Binding | Thread sewning binding, flexi-bound binding, saddle-stitching binding, glue binding, wire-o binding, spiral binding,casebound binding, etc. | |||

| Certification | ISO9001, FSC | |||

| Design | From Clients,OEM | |||

| Size | Decided by Client | |||

| Printing | CMYK or Pantone | |||

| Artwork Format | AI, PDF, ID, PS, CDR | |||

| Finishing | Gloss or Matt Lamination, Spot UV, Emboss, Deboss and Sprayed Edges | |||

Creating a book with luxury sprayed edges involves a specialized printing technique that adds a touch of elegance to the finished product. Here's a guide to help you achieve high-quality results for luxury sprayed book edges printing:

1. Choose High-Quality Paper:

Paper Weight: Opt for a premium and heavy paper stock to enhance the overall feel of the book.

Coating: A coated paper can help the sprayed edges adhere better and provide a smoother finish.

2. Design Considerations:

Bleed and Trim Marks: Include bleed and trim marks to ensure the sprayed edges cover the entire edge without leaving any white spaces.

Color Choice: Select colors that complement the book cover or theme, enhancing the overall aesthetic.

3. Select the Right Printing Company:

Experience with Sprayed Edges: Choose a printer with experience in luxury book printing, specifically with sprayed edges.

Samples and Portfolio: Request samples or review their portfolio to assess the quality of their sprayed edge work.

4. Prepress Preparation:

Color Management: Ensure your design uses CMYK color mode for accurate color reproduction.

High-Resolution Images: Use high-resolution images to maintain sharpness during the printing process.

5. Spray Technique:

Spray Type: There are different spray techniques, including airbrushing and pressurized spray systems. Discuss options with your printer to determine the best method for your project.

Masking: Mask off areas of the book that you don't want to be sprayed. This ensures a clean and precise finish.

6. Color Matching:

Pantone Colors: If you have specific color requirements, provide Pantone color codes to ensure accurate color matching for the sprayed edges.

Print Proof: Request a print proof to verify that the sprayed edges match your expectations before proceeding with the full print run.

7. Drying Time:

Allow Sufficient Drying Time: Sprayed edges require drying time. Ensure that the printer allows enough time for the edges to dry completely before handling or packaging.

8. Quality Control:

Inspect Samples: Before the full production run, inspect samples for color accuracy, evenness of the spray, and overall quality.

Consistency: Ensure that the sprayed edges are consistent across the entire print run.

9. Protective Coating:

Optional Clear Coat: Consider adding a clear protective coating over the sprayed edges for durability and to prevent color transfer.

10. Packaging and Handling:

Protective Packaging: Use packaging that protects the sprayed edges during shipping and handling.

Handling Instructions: Provide instructions to readers on how to handle the book to preserve the sprayed edges.

E-mail: sales01@seseprinting.com

Mobile phone: +86-13570912663

WhatsApp: 008613501482344

Tel: +86-020-34613569

Add: 702 No. 21 Huizhong Road, Shiqiao St, Panyu District. Guangzhou city, Guangdong Province. China