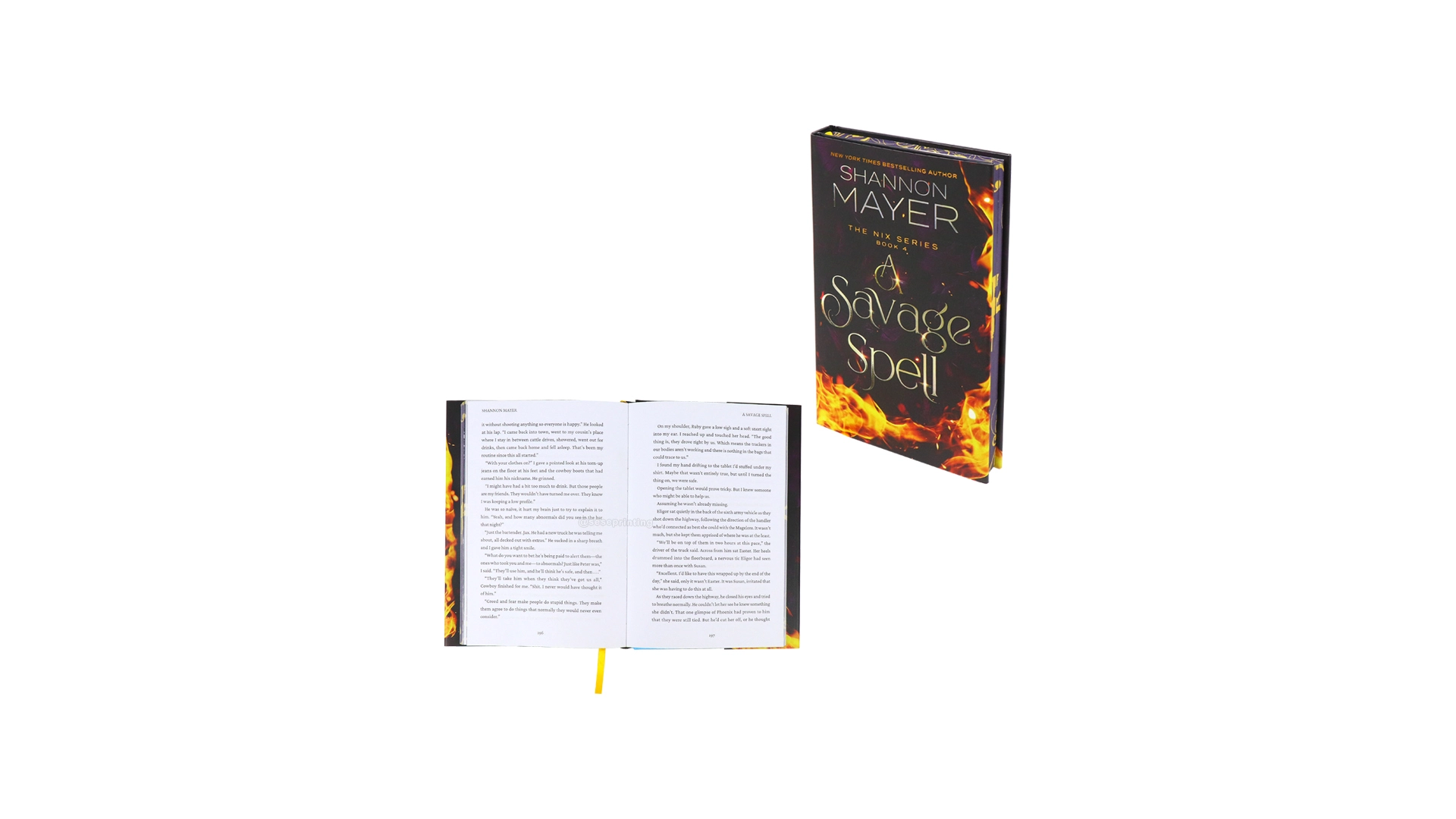

Foiled Hardcover Book Printing Luxurious Special Edition Book

Combining foiled hardcover printing with sprayed edges requires careful planning and coordination to achieve a cohesive and premium result.

Foiled Hardcover Book Printing Luxurious Special Edition Book

| Product Name | Foiled Book Print | |||

| Material | Glossy/matt art paper, offset paper, woodfree paper, writing paper, light coated paper, special type paper, C1S C2S board,C1S grey board, kraft paper, light weight coated paper, wood free paper, and so on. | |||

| Binding | Thread sewning binding, flexi-bound binding, saddle-stitching binding, glue binding, wire-o binding, spiral binding,casebound binding, etc. | |||

| Certification | ISO9001, FSC | |||

| Design | From Clients,OEM | |||

| Size | Decided by Client | |||

| Printing | CMYK or Pantone | |||

| Artwork Format | AI, PDF, ID, PS, CDR | |||

| Finishing | Gloss or Matt Lamination, Spot UV, Emboss, Deboss and Sprayed Edges | |||

Combining foiled hardcover book printing with sprayed edges can create a visually stunning and premium-quality book. Here's a step-by-step guide on how to achieve this sophisticated finish:

Design Your Book:

Work with a professional graphic designer to create a visually appealing cover design that incorporates foil elements. Ensure that the design complements the overall theme of the book.

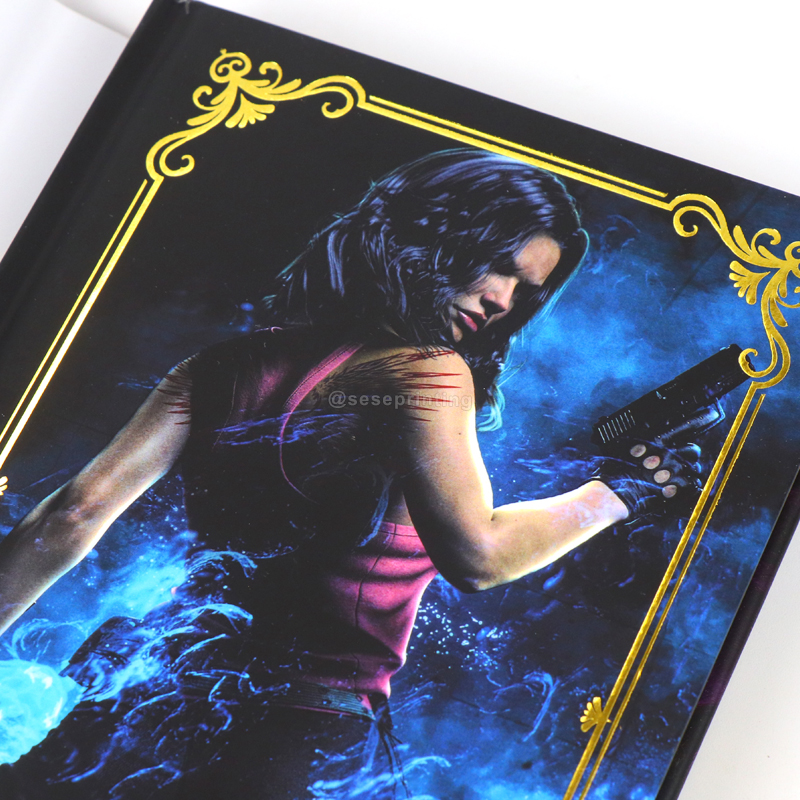

Select Foil Colors and Areas:

Decide on the foil colors you want to use for the cover. Common choices include gold, silver, copper, or holographic foils. Determine which parts of the design will be foiled, such as text, illustrations, or specific elements.

Design Foiling Die:

Create a foiling die based on your design. The foiling die is a custom stamp that presses the foil onto the cover during the printing process.

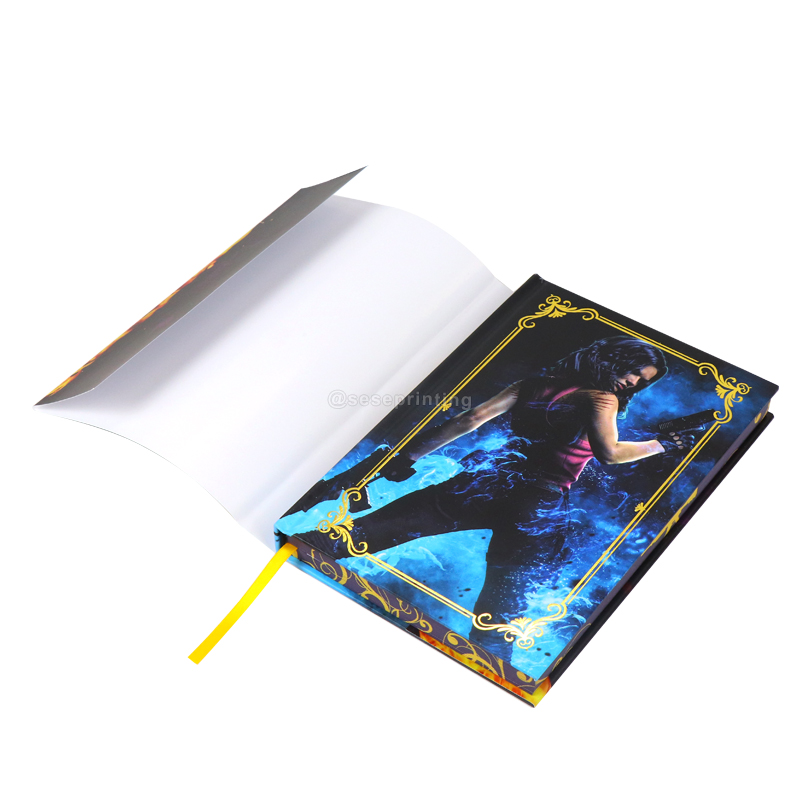

Choose Hardcover Material:

Select a high-quality hardcover material for the book. This could include options like cloth, leather, or a specialty paper that complements the foiling and overall design.

Foiling Process:

Coordinate with a printing company that specializes in foiling. During the printing process, the foiling die is used to apply heat and pressure to transfer the foil onto the cover material. This creates a luxurious, metallic finish.

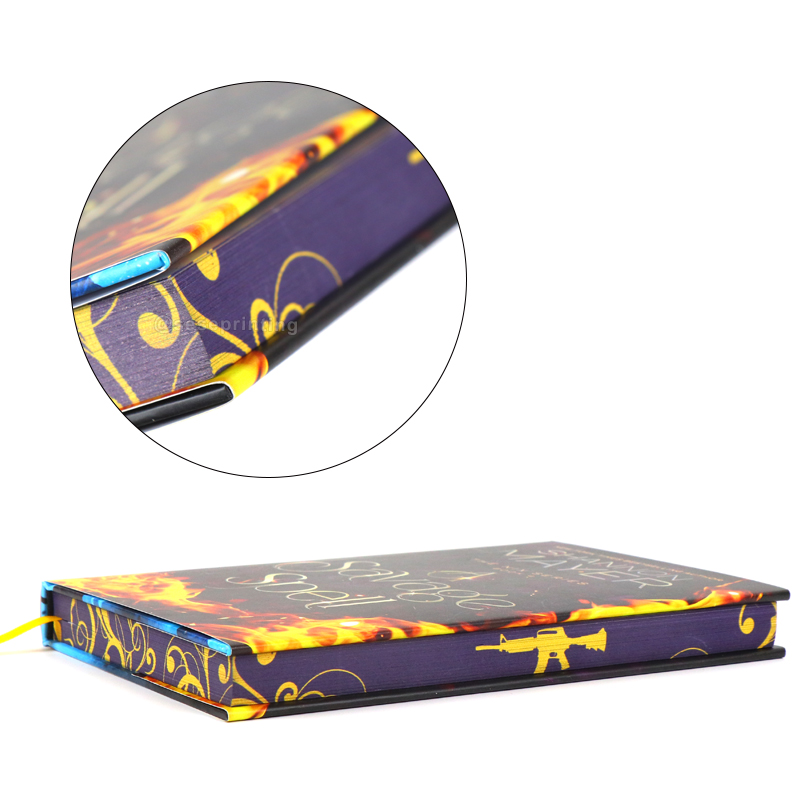

Sprayed Edges Design:

Plan the design for sprayed edges that will complement the cover. Consider coordinating the color of the sprayed edges with the foil on the cover for a cohesive look.

Sprayed Edges Application:

After the foiling process is complete, the sprayed edges are applied. This involves using an airbrush or similar method to evenly spray the edges of the book block (all the pages) with the chosen color.

Quality Control:

Conduct quality control checks throughout the process to ensure that the foiling and sprayed edges are applied consistently and accurately. Check for any imperfections or inconsistencies.

Additional Finishing Options:

Consider additional finishing options, such as embossing or debossing, to further enhance the tactile and visual appeal of the book.

Protective Coating:

Apply a protective coating to the cover to ensure the durability of the foil and prevent scratching or wear.

Print Test Sample:

Print a small batch of test copies to assess the final product. This step allows you to make any necessary adjustments before proceeding with a full print run.

Full Production:

Once you are satisfied with the test copies, proceed with the full production of the foiled hardcover books with sprayed edges.

Packaging and Presentation:

Consider premium packaging for the finished books to enhance the overall presentation. This may include slipcases, dust jackets, or other decorative elements.

Limited Editions:

Position your book as a limited edition or collector's item to add exclusivity and appeal to a niche market.

E-mail: sales01@seseprinting.com

Mobile phone: +86-13570912663

WhatsApp: 008613501482344

Tel: +86-020-34613569

Add: 702 No. 21 Huizhong Road, Shiqiao St, Panyu District. Guangzhou city, Guangdong Province. China