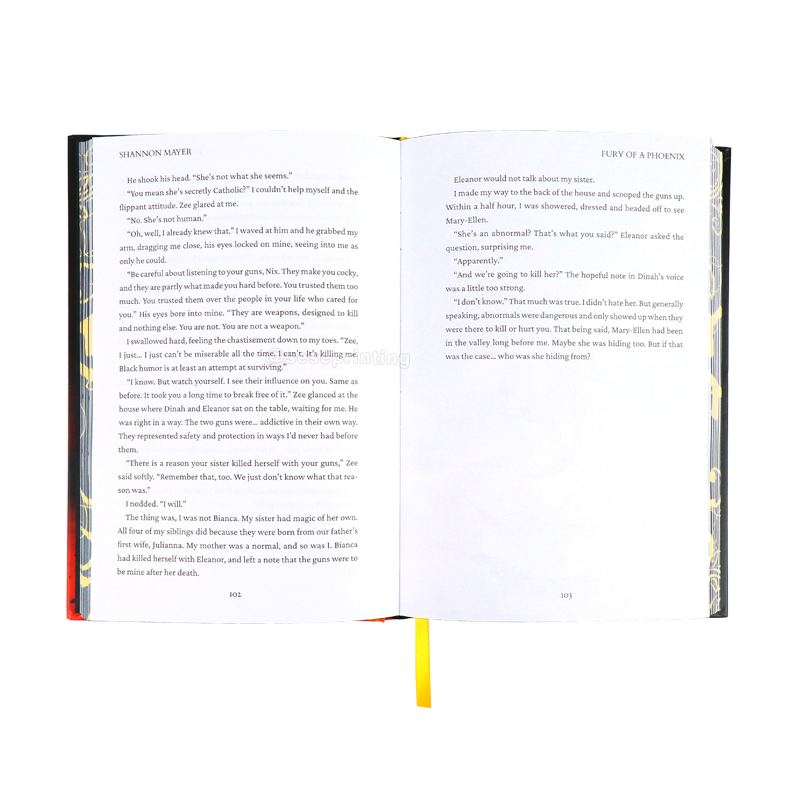

Publishing Book Printing Hardback Special Book with Sprayed Edges

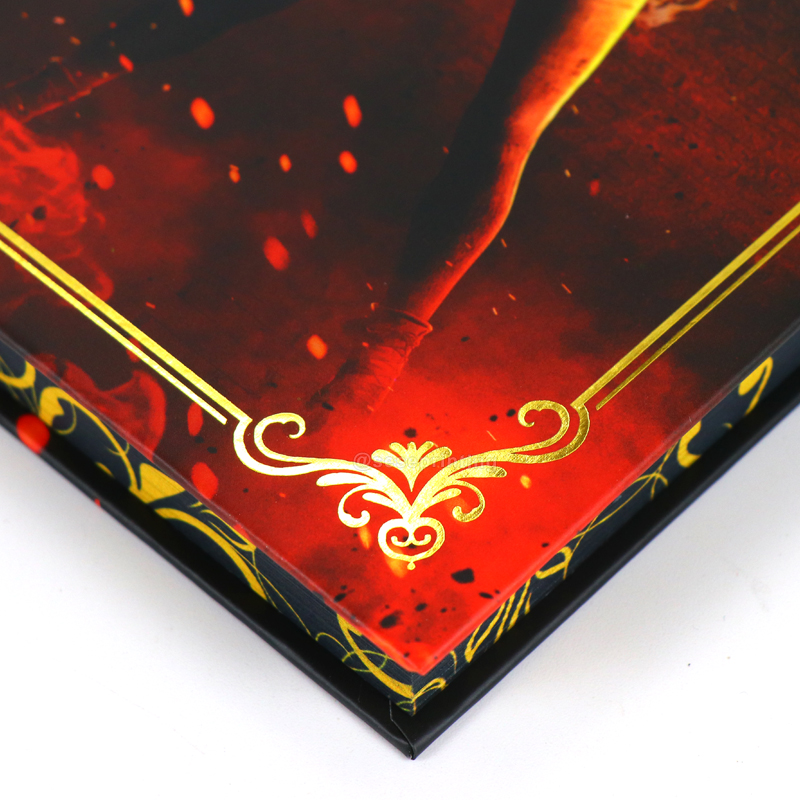

Discover the allure of our exquisite hardcover sprayed edges book, this visually stunning hardcover book featuring sprayed edges, a testament to craftsmanship and sophistication.

Publishing Book Printing Hardback Special Book with Sprayed Edges

| Product Name | Special Book | |||

| Material | Glossy/matt art paper, offset paper, woodfree paper, writing paper, light coated paper, special type paper, C1S C2S board,C1S grey board, kraft paper, light weight coated paper, wood free paper, and so on. | |||

| Binding | Thread sewning binding, flexi-bound binding, saddle-stitching binding, glue binding, wire-o binding, spiral binding,casebound binding, etc. | |||

| Certification | ISO9001, FSC | |||

| Design | From Clients,OEM | |||

| Size | Decided by Client | |||

| Printing | CMYK or Pantone | |||

| Artwork Format | AI, PDF, ID, PS, CDR | |||

| Finishing | Gloss or Matt Lamination, Spot UV, Emboss, Deboss and Sprayed Edges | |||

Printing a hardback special book with sprayed edges involves a combination of traditional bookbinding techniques and specialized finishing processes. Sprayed edges add a unique and visually appealing touch to the book's appearance. Here's a general overview of the process:

Design and Layout:

Work with a professional graphic designer to create the book cover and layout, keeping in mind the dimensions of the hardback book and the desired sprayed edges effect.

Material Selection:

Choose high-quality materials for the cover, paper, and board for the hardback book. Consider factors such as paper weight, texture, and finish to enhance the overall feel and look of the book.

Printing:

Use a high-quality printing process for both the cover and interior pages. Digital or offset printing may be suitable, depending on the quantity and budget.

Hardback Binding:

Choose a durable and high-quality binding method for the hardback book. This typically involves sewing the signatures (groups of pages) together, attaching them to the book's spine, and affixing the cover.

Sprayed Edges:

After the book is bound, the sprayed edges can be applied. This process involves spraying a color or metallic finish onto the edges of the closed book. This can be done manually or using specialized equipment to ensure an even and professional finish.

Drying:

Allow sufficient time for the sprayed edges to dry completely before moving on to the next step. The drying time will depend on the type of spray used.

Finishing Touches:

Apply any additional finishing touches, such as foil stamping, embossing, or debossing, to enhance the overall design and quality of the book.

Quality Control:

Conduct a thorough quality check to ensure that the book meets the desired standards. This includes checking for any printing defects, binding issues, or imperfections in the sprayed edges.

Packaging and Distribution:

Once the books pass quality control, they can be packaged and prepared for distribution. Consider protective packaging to prevent damage during shipping.

E-mail: sales01@seseprinting.com

Mobile phone: +86-13570912663

WhatsApp: 008613501482344

Tel: +86-020-34613569

Add: 702 No. 21 Huizhong Road, Shiqiao St, Panyu District. Guangzhou city, Guangdong Province. China