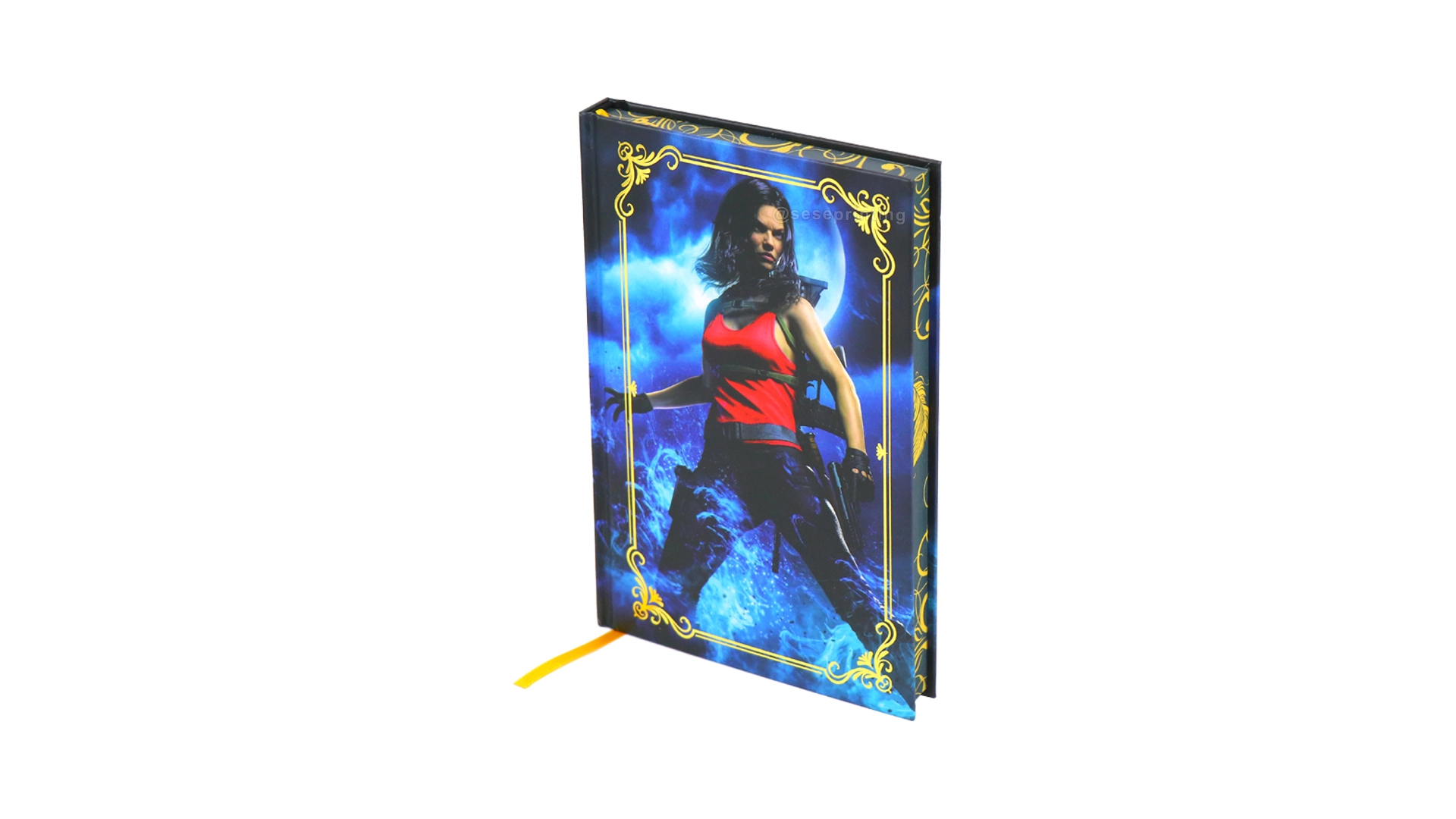

Special Edition Books Printing with Black Pages and Foiled Cover

Our precision and attention to detail redefine book aesthetics, creating a visual masterpiece that complements your literary work. Choose our sprayed edges printing to transform your book into a captivating work of art, leaving a lasting impression on readers and collectors alike.

Printing Luxury Hardback Book with Foil Stamping and Sprayed Edges

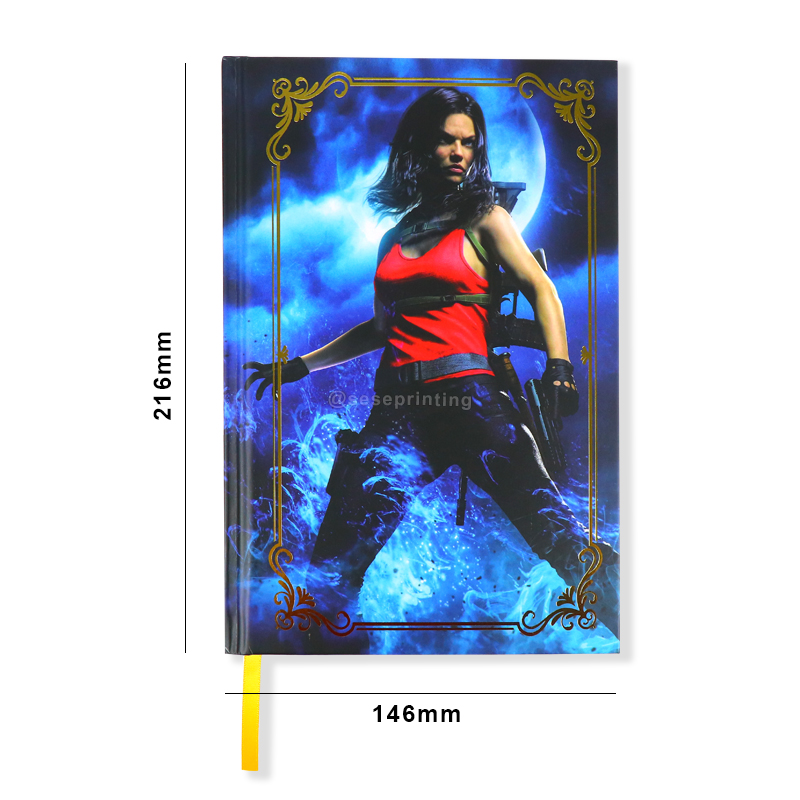

| Product Name | Sprayed Edges Book | |||

| Material | Glossy/matt art paper, offset paper, woodfree paper, writing paper, light coated paper, special type paper, C1S C2S board,C1S grey board, kraft paper, light weight coated paper, wood free paper, and so on. | |||

| Binding | Thread sewning binding, flexi-bound binding, saddle-stitching binding, glue binding, wire-o binding, spiral binding,casebound binding, etc. | |||

| Certification | ISO9001, FSC | |||

| Design | From Clients,OEM | |||

| Size | Decided by Client | |||

| Printing | CMYK or Pantone | |||

| Artwork Format | AI, PDF, ID, PS, CDR | |||

| Finishing | Gloss or Matt Lamination, Spot UV, Emboss, Deboss and Sprayed Edges | |||

Special effects in book printing, such as foil stamping and embossing, can add a touch of elegance and sophistication to the final product. These techniques not only enhance the visual appeal of the book but also provide a tactile experience for the reader. Here are some popular special effects used in book printing:

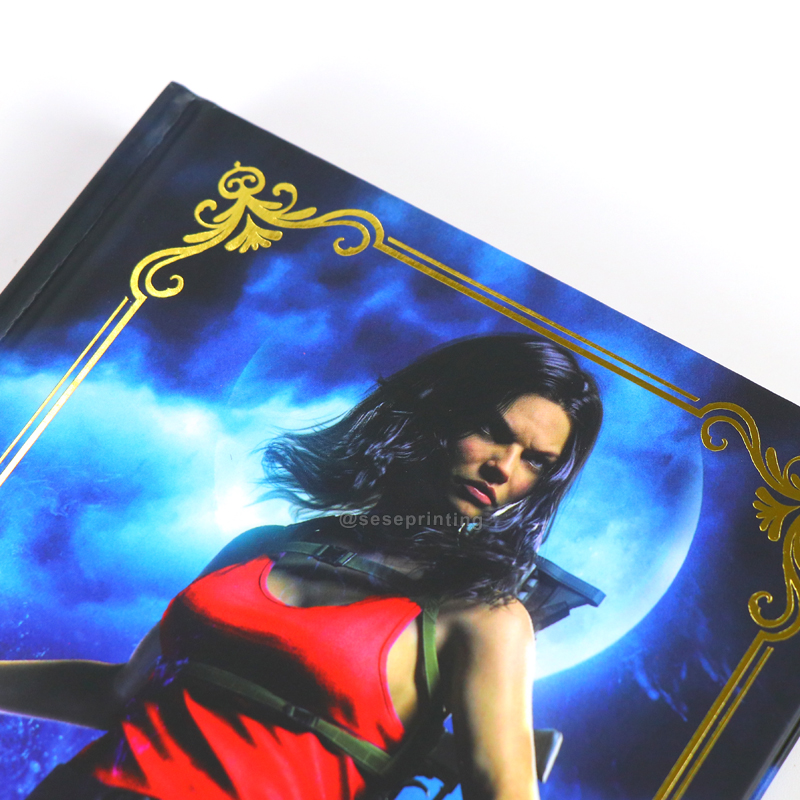

Foil Stamping:

Process: Foil stamping involves applying a thin layer of metallic or pigmented foil to the cover or specific parts of the book using a heated die. The heat activates the adhesive on the back of the foil, causing it to bond with the paper or cover.

Effects: Foil stamping can create metallic, glossy, or matte finishes, adding a luxurious and eye-catching element to the book. Common foil colors include gold, silver, copper, and various shades.

Embossing:

Process: Embossing is the technique of creating raised or recessed relief images and designs on the cover or pages of a book. A die is used to press the paper or cover into a three-dimensional shape.

Effects: Embossing adds texture and depth to the printed material, making certain elements stand out. It can be used for logos, titles, or decorative patterns.

Debossing:

Process: Debossing is the opposite of embossing. Instead of creating raised elements, debossing involves pressing the design into the paper or cover, creating a depressed or indented effect.

Effects: Debossing provides a subtle and sophisticated look, often used for minimalist designs or to add a tactile quality to specific elements.

Spot UV Coating:

Process: Spot UV coating involves applying a clear, glossy coating to specific areas of the book, creating a contrast between the shiny and matte surfaces.

Effects: This technique is commonly used to highlight specific images, text, or design elements, giving them a reflective and visually appealing quality.

Die Cutting:

Process: Die cutting involves using a die to cut specific shapes or patterns out of the cover or pages of a book.

Effects: Die cutting can be used for creating unique shapes, windows, or openings in the cover, adding an extra layer of creativity to the design.

Metallic Inks:

Process: Metallic inks contain metallic particles that produce a shiny, metallic finish when printed on paper.

Effects: Metallic inks can be used for printing text, illustrations, or entire covers, providing a metallic sheen without the need for foil stamping.

E-mail: sales01@seseprinting.com

Mobile phone: +86-13570912663

WhatsApp: 008613501482344

Tel: +86-020-34613569

Add: 702 No. 21 Huizhong Road, Shiqiao St, Panyu District. Guangzhou city, Guangdong Province. China