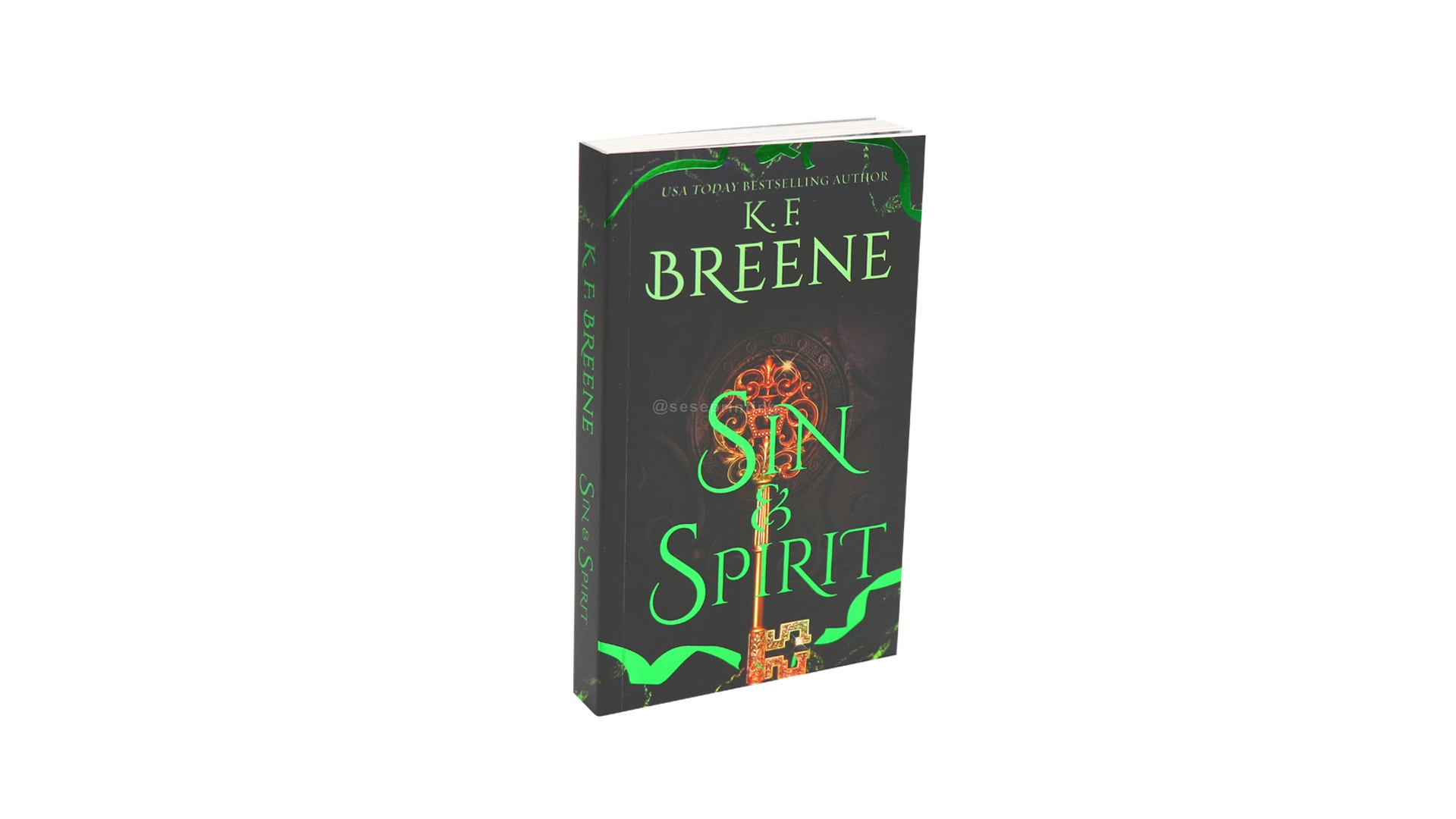

Paperback Novel Manufacturer Customized Softcover Book Printing

The art of paperback printing encompasses a blend of traditional craftsmanship and modern technologies, ensuring that each book is a well-crafted and visually appealing piece of literature.

Paperback Novel Manufacturer Customized Softcover Book Printing

| Product Name | Softcover Books | |||

| Material | Glossy/matt art paper, offset paper, woodfree paper, writing paper, light coated paper, special type paper, C1S C2S board,C1S grey board, kraft paper, light weight coated paper, wood free paper, and so on. | |||

| Binding | Thread sewning binding, flexi-bound binding, saddle-stitching binding, glue binding, wire-o binding, spiral binding,casebound binding, etc. | |||

| Certification | ISO9001, FSC | |||

| Design | From Clients,OEM | |||

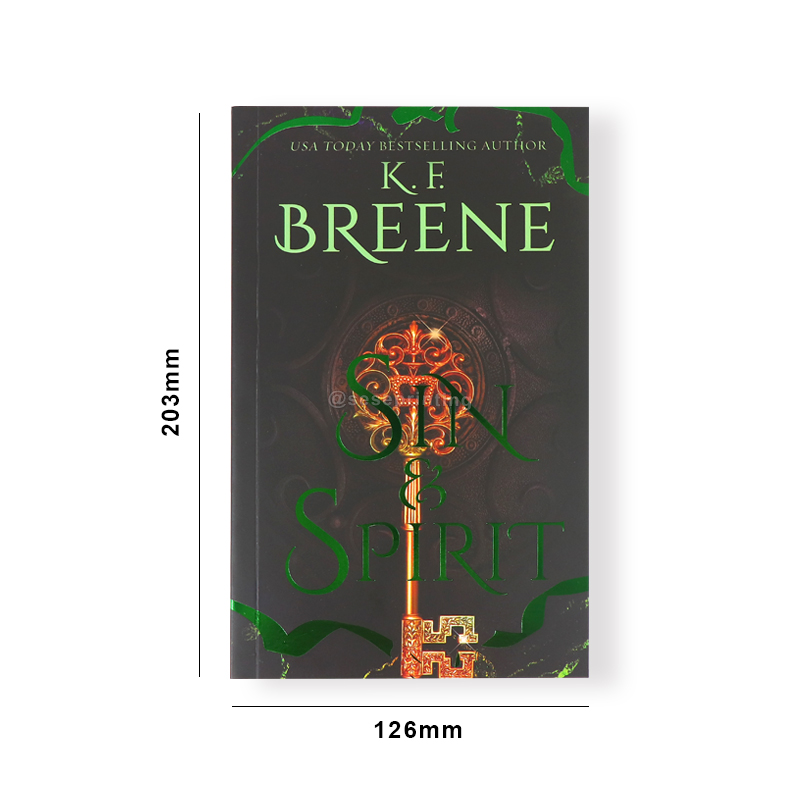

| Size | Decided by Client | |||

| Printing | CMYK or Pantone | |||

| Artwork Format | AI, PDF, ID, PS, CDR | |||

| Finishing | Gloss or Matt Lamination, Spot UV, Emboss, Deboss and Sprayed Edges | |||

Creating paperback books involves a meticulous process that combines craftsmanship, technology, and artistic elements. Here's an overview of the art behind paperback printing:

Prepress Preparation:

Manuscript Review: Before printing begins, the manuscript undergoes a thorough review for formatting, errors, and layout issues.

Typesetting: The text is formatted according to the chosen book size and layout specifications.

Cover Design:

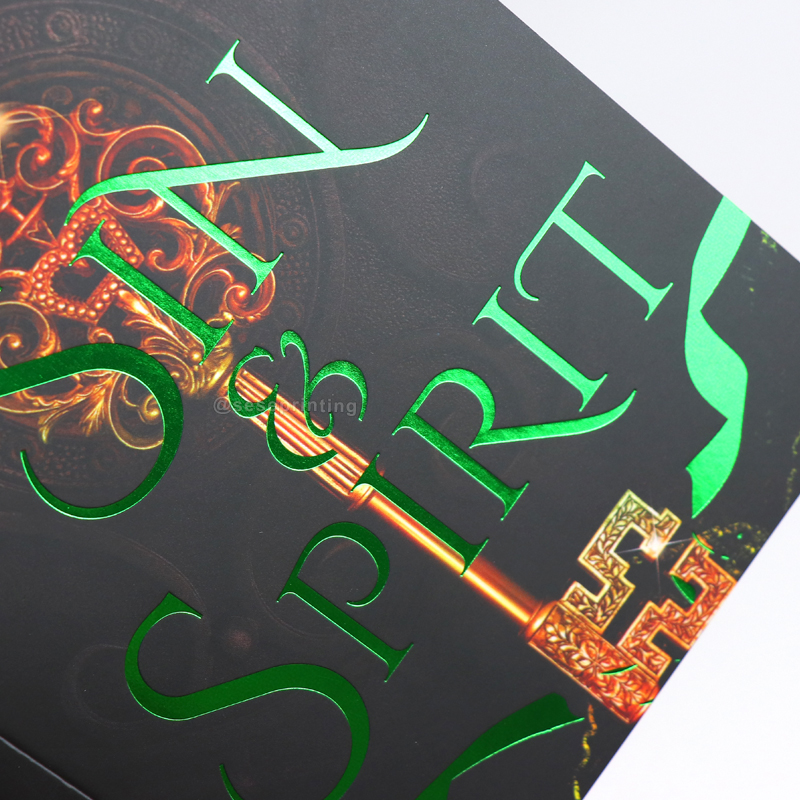

Graphic Design: A visually appealing cover is designed, often including artwork, typography, and other elements that convey the book's theme.

Color Selection: Cover colors are chosen carefully, considering the genre, target audience, and market trends.

Printing Technology:

Offset Printing: Traditional offset printing is commonly used for paperback books. It involves transferring ink from a plate to a rubber blanket and then onto the printing surface.

Digital Printing: Some publishers opt for digital printing, which is cost-effective for small print runs and allows for on-demand printing.

Paper Selection:

Paper Quality: The choice of paper significantly impacts the book's feel and durability. Factors like weight, texture, and color are considered.

Sustainability: Many publishers now focus on environmentally friendly paper options to reduce their ecological footprint.

Binding Process:

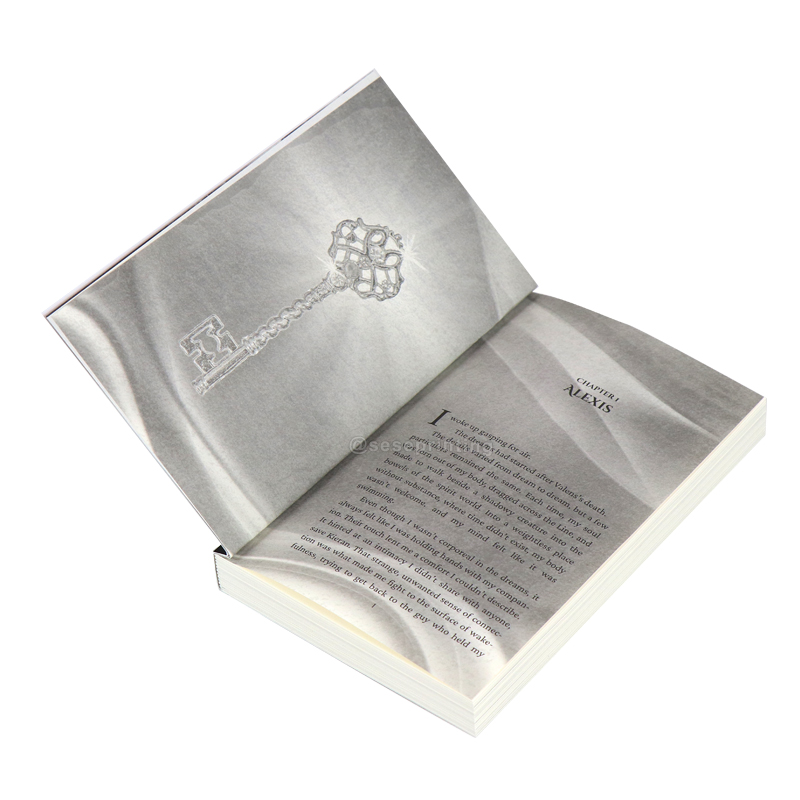

Perfect Binding: Most paperback books use perfect binding, where the pages are glued together at the spine. This method provides a clean and professional appearance.

Saddle Stitching: This method involves stapling the pages together along the spine and is common for shorter publications.

Trimming and Folding:

Trimming: After printing, the edges of the book are trimmed for a neat finish.

Folding: For signatures or multiple-page sections, folding is done before binding.

Quality Control:

Inspection: Each printed book undergoes quality checks to ensure accurate colors, proper binding, and overall print quality.

Proofreading: Even after the manuscript is typeset, a final proofreading is conducted to catch any last-minute errors.

Finishing Touches:

Lamination or Coating: Some books receive a protective layer for added durability and a polished appearance.

Embossing/Debossing: Raised or recessed designs on the cover add a tactile and decorative element.

E-mail: sales01@seseprinting.com

Mobile phone: +86-13570912663

WhatsApp: 008613501482344

Tel: +86-020-34613569

Add: 702 No. 21 Huizhong Road, Shiqiao St, Panyu District. Guangzhou city, Guangdong Province. China