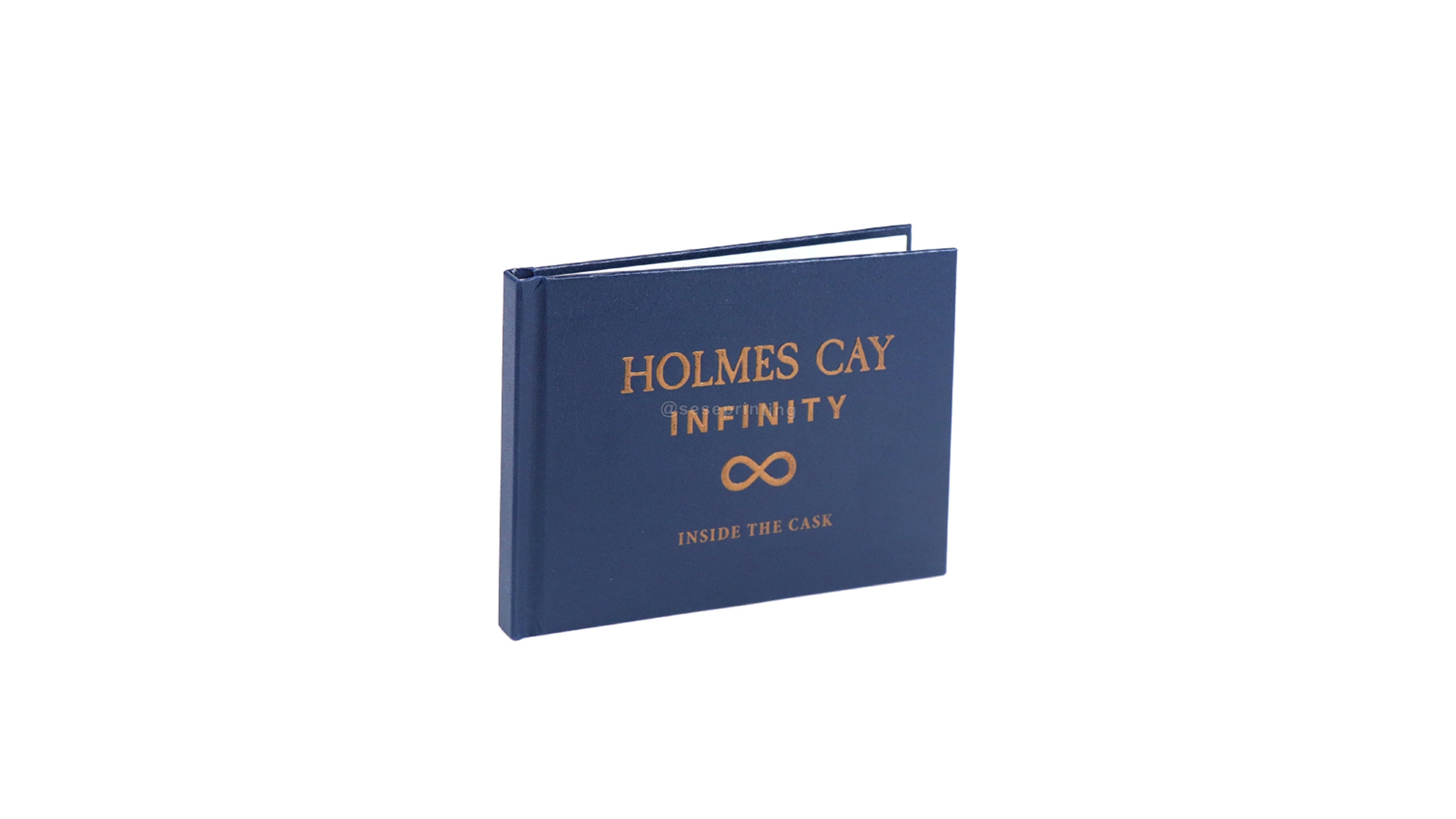

Custom Embossed Logo Magazine Printing Leather Cover Brochure

Our expert team delivers high-quality, bespoke magazines tailored to your unique vision. Elevate your publication with professional printing that captivates your audience and showcases your content in style. Explore our custom options today!

Custom Embossed Logo Magazine Printing Leather Cover Brochure

| Product Name | Catalog Printing | |||

| Material | Glossy/matt art paper, offset paper, woodfree paper, writing paper, light coated paper, special type paper, C1S C2S board,C1S grey board, kraft paper, light weight coated paper, wood free paper, and so on. | |||

| Binding | Thread sewning binding, flexi-bound binding, saddle-stitching binding, glue binding, wire-o binding, spiral binding,casebound binding, etc. | |||

| Certification | ISO9001, FSC | |||

| Design | From Clients,OEM | |||

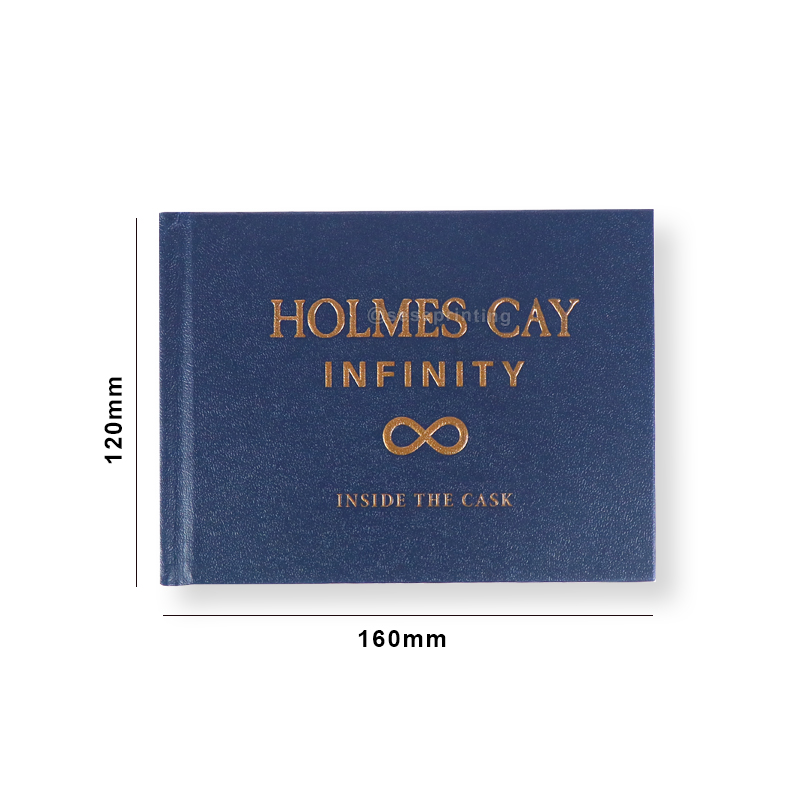

| Size | Decided by Client | |||

| Printing | CMYK or Pantone | |||

| Artwork Format | AI, PDF, ID, PS, CDR | |||

| Finishing | Gloss or Matt Lamination, Spot UV, Embossed, Debossed and Sprayed Edges | |||

Custom magazine printing involves the production of magazines tailored to specific requirements, preferences, and designs. Here's a basic guide on how the process typically works:

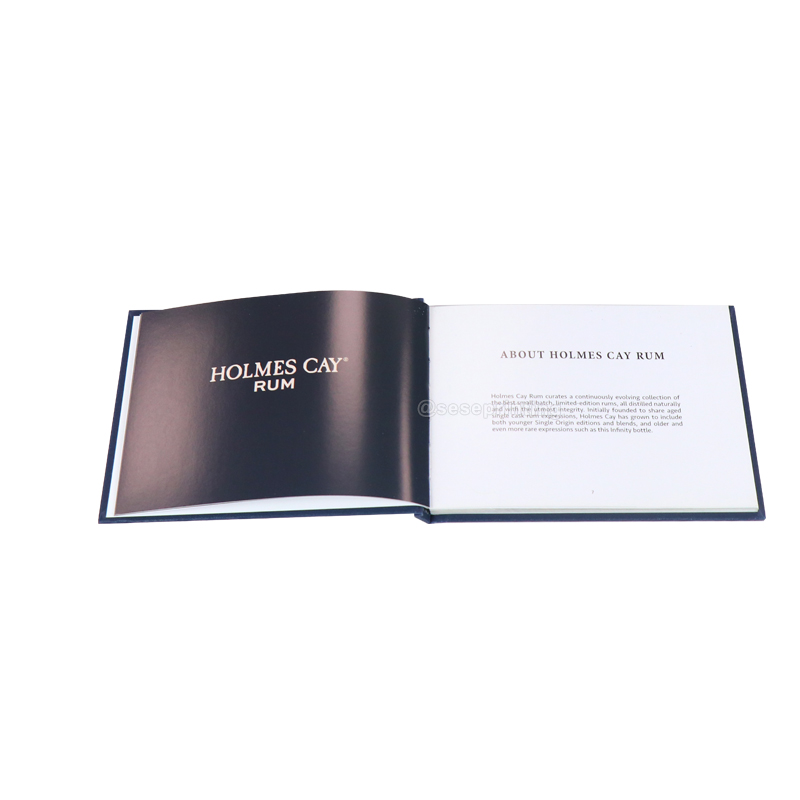

Planning and Design: Begin by conceptualizing the content, layout, and design of your magazine. Determine the target audience, theme, and style. You may choose to work with a graphic designer or use design software to create your magazine layout.

Content Creation: Generate or gather the content for your magazine, including articles, images, advertisements, and other relevant materials. Ensure that the content aligns with your magazine's theme and target audience.

Print Specifications:

Paper Type:

The paper type will affect the look and feel of your magazine. Common options include coated (glossy or matte) and uncoated paper.

Coated paper is often preferred for magazines as it offers better color reproduction and image sharpness. Matte coatings provide a more subdued look, while glossy coatings offer a shiny finish.

Consider the paper weight as well, which can range from lightweight for inner pages to heavier weight for covers.

Size:

Magazine sizes can vary, but common options include standard sizes like 8.5x11 inches (letter size) or 8.25x10.75 inches (digest size).

You can also choose a custom size to fit your specific design and content requirements.

Color Options:

Full-color printing is standard for magazines to showcase images and graphics effectively.

Discuss color profiles and proofing options with your printer to ensure accurate color reproduction.

Binding:

Saddle Stitching: This is a common binding method for magazines where folded sheets are stapled together along the spine. It's suitable for magazines with a lower page count.

Perfect Binding: Ideal for thicker magazines, perfect binding involves gluing the pages to the spine of the cover. It offers a clean and professional look.

Wire-O Binding: In this method, metal wires are threaded through punched holes along the spine, allowing the magazine to lay flat when open. It's suitable for magazines that need to be fully opened and have a longer shelf life.

Additional Options:

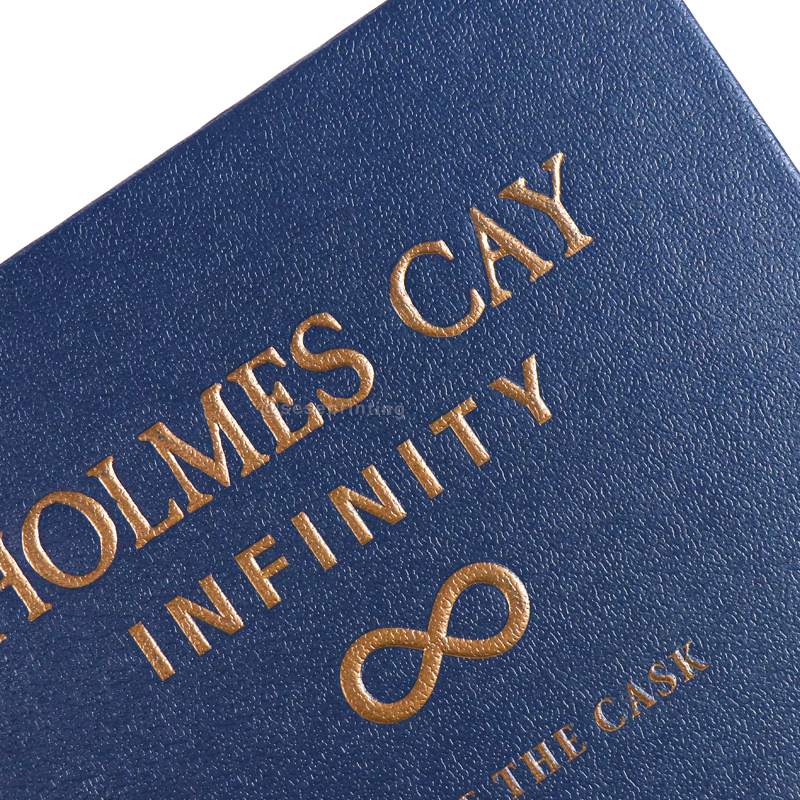

Cover Finishes: Consider options like spot UV coating, embossing, debossing, or foil stamping to enhance the look of your magazine cover.

Specialty Printing Techniques: Explore options like metallic inks, fluorescent inks, or textured paper for a unique and eye-catching finish.

Special Inserts or Foldouts: Add inserts, gatefolds, or other special features to make certain articles or advertisements stand out.

Request for Quote: Contact us to request a quote based on your print specifications, quantity, and timeline. Ensure that the quote includes all relevant costs, such as printing, shipping, and any additional services you may require.

Proofing: Before proceeding with full-scale printing, request a proof of your magazine to review for any errors or issues. This step allows you to make necessary corrections and adjustments before final production.

Printing: Once the proof is approved, proceed with printing and binding your magazines. The printing company will use offset or digital printing technology to produce the desired number of copies according to your specifications.

Quality Control: During the printing process, conduct quality control checks to ensure that the printed magazines meet your standards in terms of color accuracy, image resolution, text clarity, and overall print quality.

Finishing and Packaging: After printing, the magazines may undergo additional finishing processes such as trimming, folding, and binding. They will then be packaged securely for distribution or delivery.

E-mail: sales01@seseprinting.com

Mobile phone: +86-13570912663

WhatsApp: 008613501482344

Tel: +86-020-34613569

Add: 702 No. 21 Huizhong Road, Shiqiao St, Panyu District. Guangzhou city, Guangdong Province. China