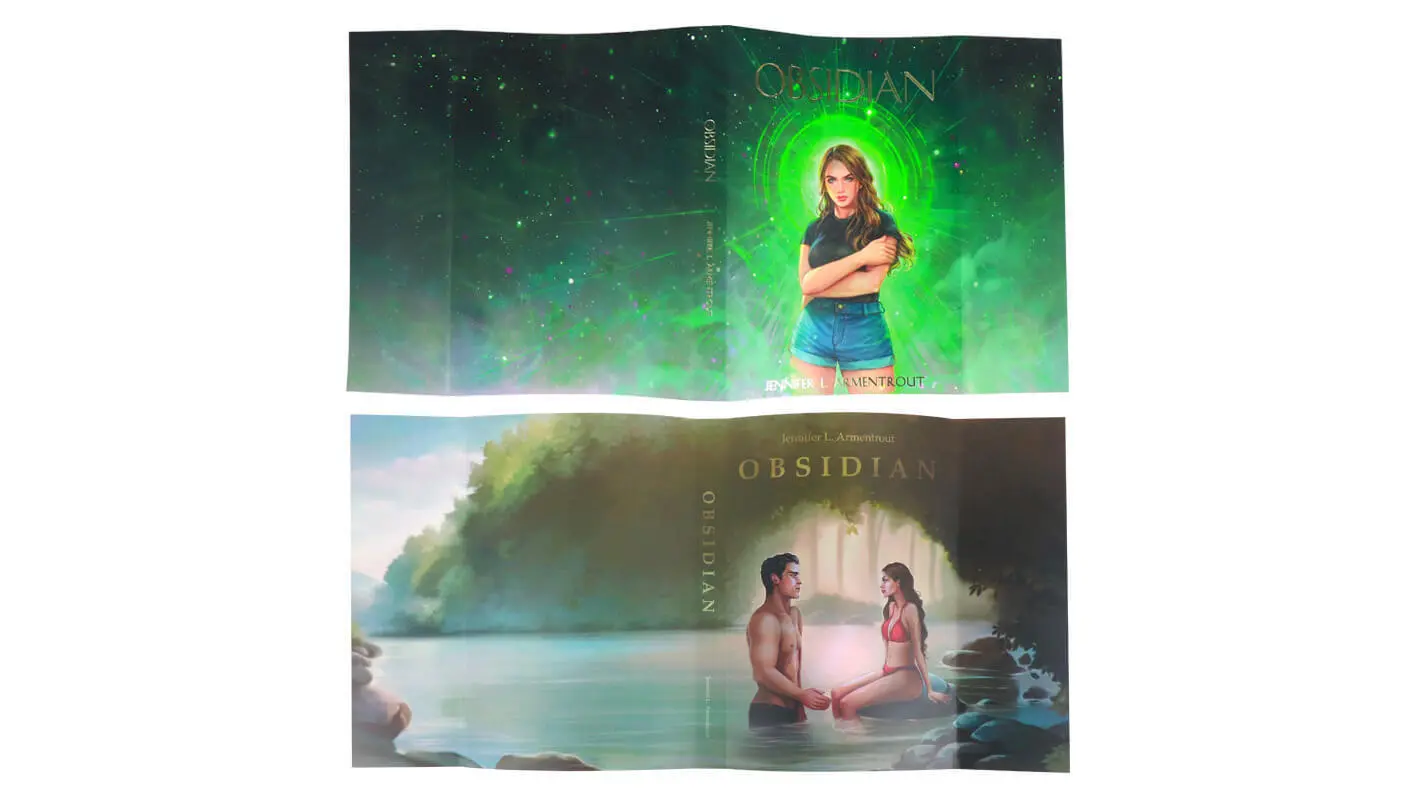

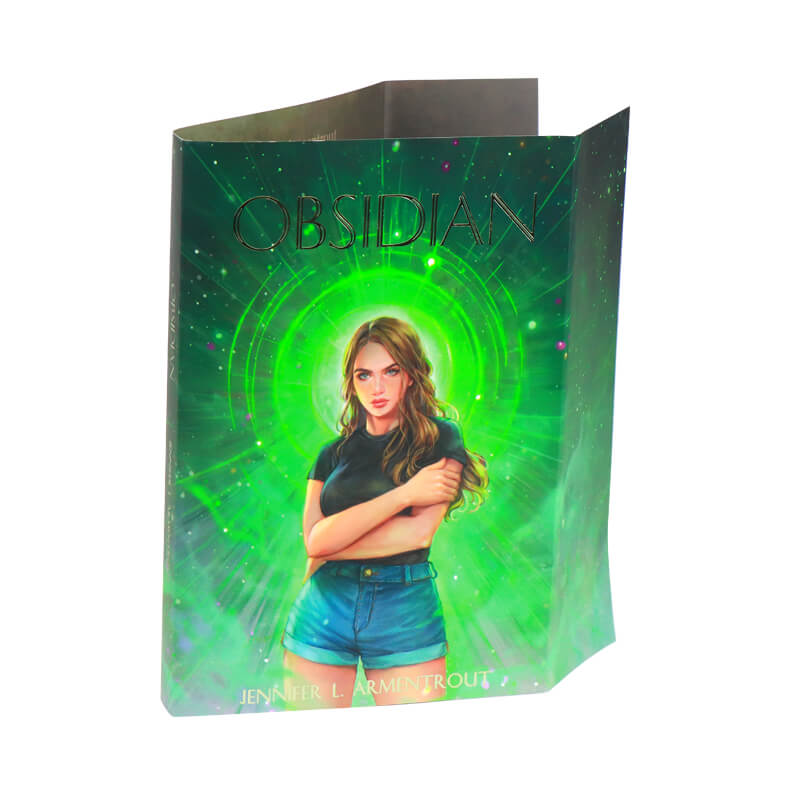

Full Color Double Sided Dust Jacket Printing with Silver Foil Logo

Whether for novels, art books, or special editions, a silver foil dust jacket not only protects your book but also makes it a standout piece on any shelf. Discover the perfect blend of style and sophistication for your literary work today!

Full Color Double Sided Dust Jacket Printing with Silver Foil Logo

| Product Name | Dust Jackets for Book | |||

| Material | Glossy/matt art paper, offset paper, woodfree paper, writing paper, light coated paper, special type paper, C1S C2S board,C1S grey board, kraft paper, light weight coated paper, wood free paper, and so on. | |||

| Certification | ISO9001, FSC | |||

| Design | From Clients,OEM | |||

| Size | Decided by Client | |||

| Printing | CMYK or Pantone | |||

| Artwork Format | AI, PDF, ID, PS, CDR | |||

| Finishing | Gloss or Matt Lamination, Spot UV, Embossing, Debossing and Foiling | |||

Printing Process for Double-Sided Dust Jacket with Silver Foil Logo:

Design Preparation

Conceptualization: Create a design for the dust jacket, including graphics, text, and the placement of the silver foil logo.

Software: Use graphic design software to finalize the artwork. Ensure that the design adheres to print specifications.

File Setup

Color Mode: Convert the design to CMYK color mode for accurate color representation in print.

Resolution: Ensure the images are at least 300 DPI for high-quality printing.

Bleed and Trim: Set up bleed areas (typically 1/8 inch) and trim marks to ensure the design extends to the edge after cutting.

Proofing

Digital Proof: Create a digital proof for review. This allows for checking colors, alignment, and overall appearance.

Client Approval: Send the proof to the client for approval. Make any necessary revisions.

Printing

Material Selection: Choose the paper stock for the dust jacket. A heavier stock (around 100-130 lb) is often preferred for durability and a professional look.

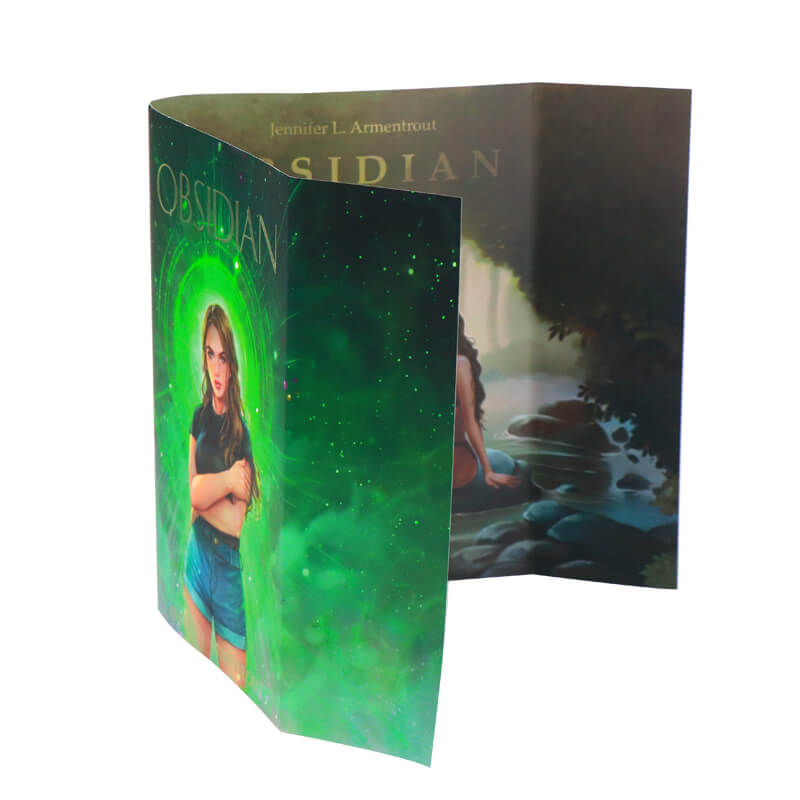

Double-Sided Printing: Use a high-quality digital or offset printing press to print the design on both sides of the selected paper.

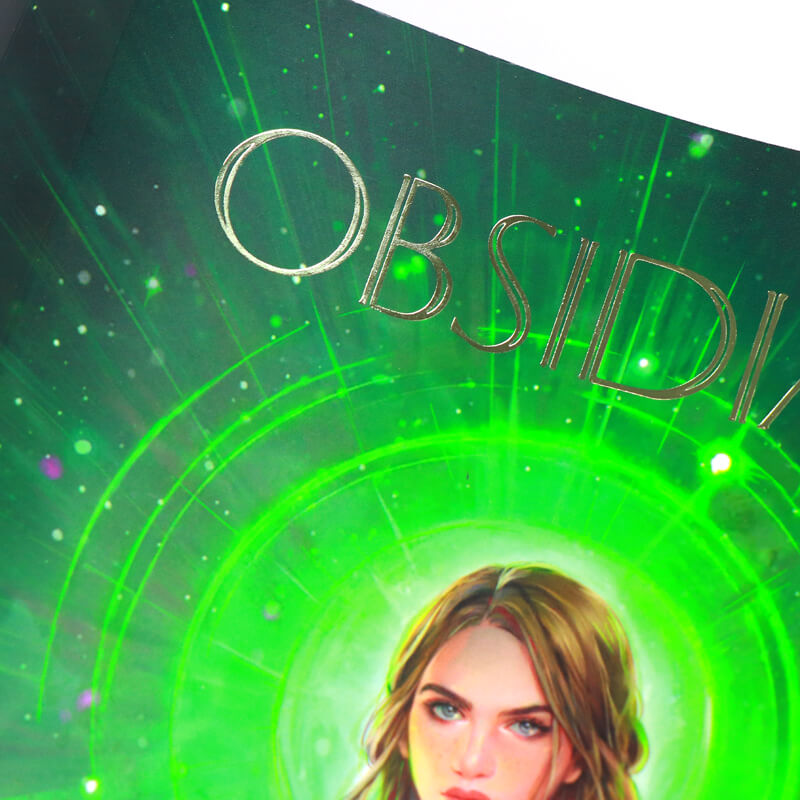

Foil Stamping

Foil Preparation: Prepare the silver foil and the stamping plate that will create the logo.

Stamping Process: Heat and pressure are applied to adhere the foil to the designated areas of the dust jacket. This process requires precision to ensure the logo is crisp and well-defined.

Finishing

Cutting: After printing and foil stamping, cut the dust jackets to the final dimensions using a precision cutter.

Folding and Scoring: Score the jackets for easier folding, if applicable, then fold them neatly.

Quality Control

Inspection: Check each dust jacket for printing quality, foil adherence, and any defects.

Final Adjustments: Make any necessary adjustments to ensure all jackets meet quality standards.

Packaging and Delivery

Packaging: Package the finished dust jackets carefully to prevent damage during transport.

Shipping: Arrange for shipping to the client, ensuring that delivery timelines are met.

E-mail: sales01@seseprinting.com

Mobile phone: +86-13570912663

WhatsApp: 008613501482344

Tel: +86-020-34613569

Add: 702 No. 21 Huizhong Road, Shiqiao St, Panyu District. Guangzhou city, Guangdong Province. China