Popular Printing Techniques for Hardcover Book Covers: A Complete Guide

Popular Printing Techniques for Hardcover Book Covers: A Complete Guide

1. Introduction

In the world of publishing, the importance of a visually striking hardcover book cover cannot be overstated. A book's cover acts as both a marketing tool and a reflection of its content, offering a glimpse of what lies inside. The printing process plays a pivotal role in shaping the look and feel of the final product, from simple full-color designs to intricate embossing and foil stamping. Whether you're an independent author or a publisher, understanding the available printing techniques will help you make informed decisions and ensure your hardcover book stands out. This guide will explore popular printing techniques for hardcover book covers, with an emphasis on custom options that allow authors, publishers, and designers to create unique and eye-catching designs.

2. Common Printing Techniques for Hardcover Book Covers

Here are the foundational techniques that printers use to create stunning hardcover covers.

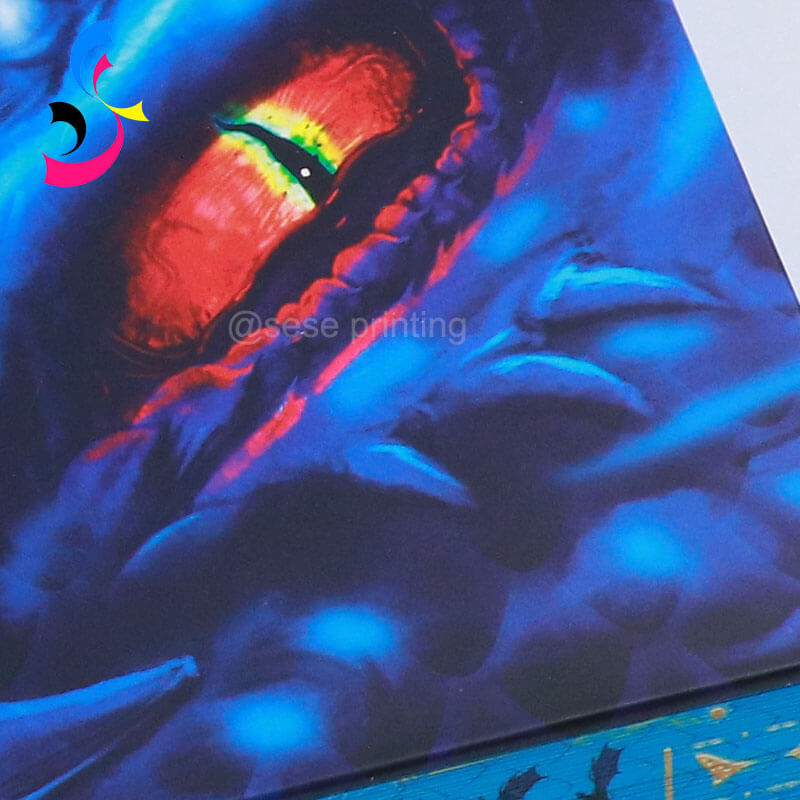

Offset Printing: This is the industry standard for high-volume, high-quality reproduction of detailed, full-color images. It uses the CMYK (Cyan, Magenta, Yellow, Key/Black) color model to create photorealistic results. It's cost-effective for large print runs but has higher setup costs, making it less ideal for small batches.

Digital Printing: Perfect for short runs and print-on-demand services. Digital printing offers quick turnaround times and is excellent for proofing. While the color gamut and sharpness can sometimes be slightly less vibrant than offset for very large quantities, the technology has advanced tremendously and delivers excellent quality for most projects.

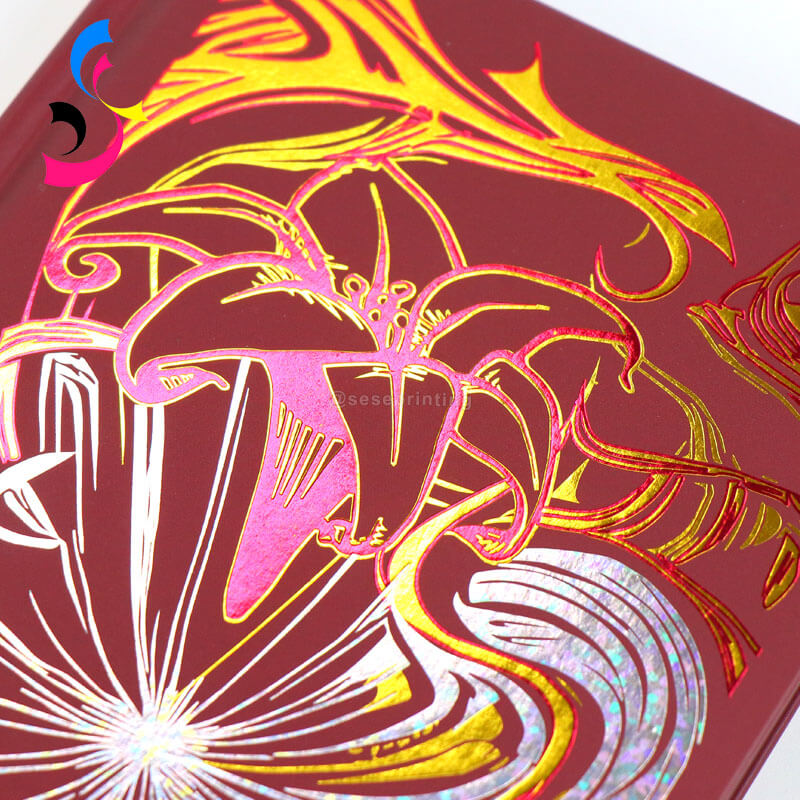

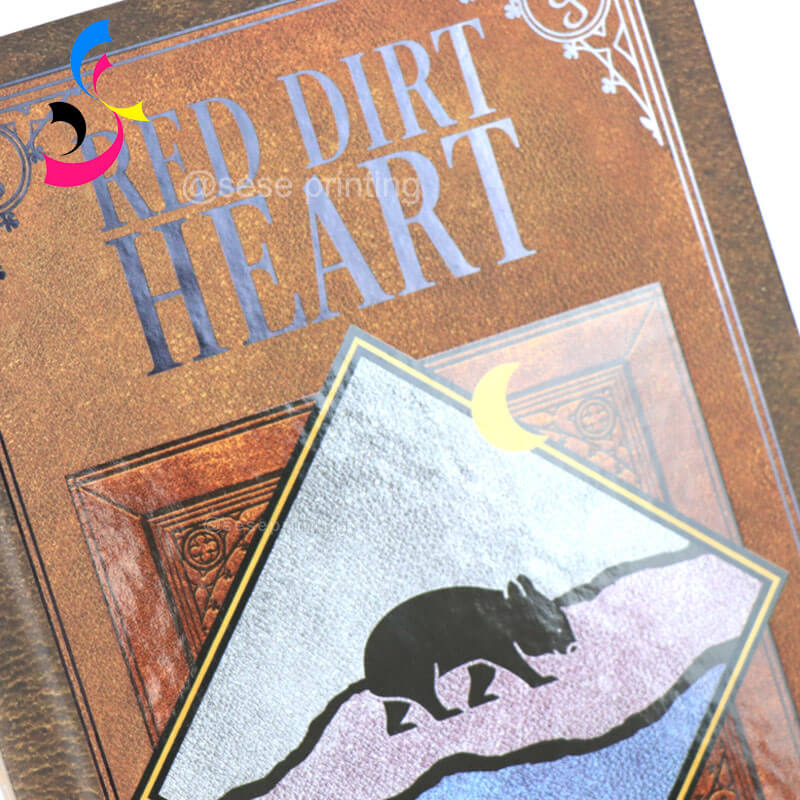

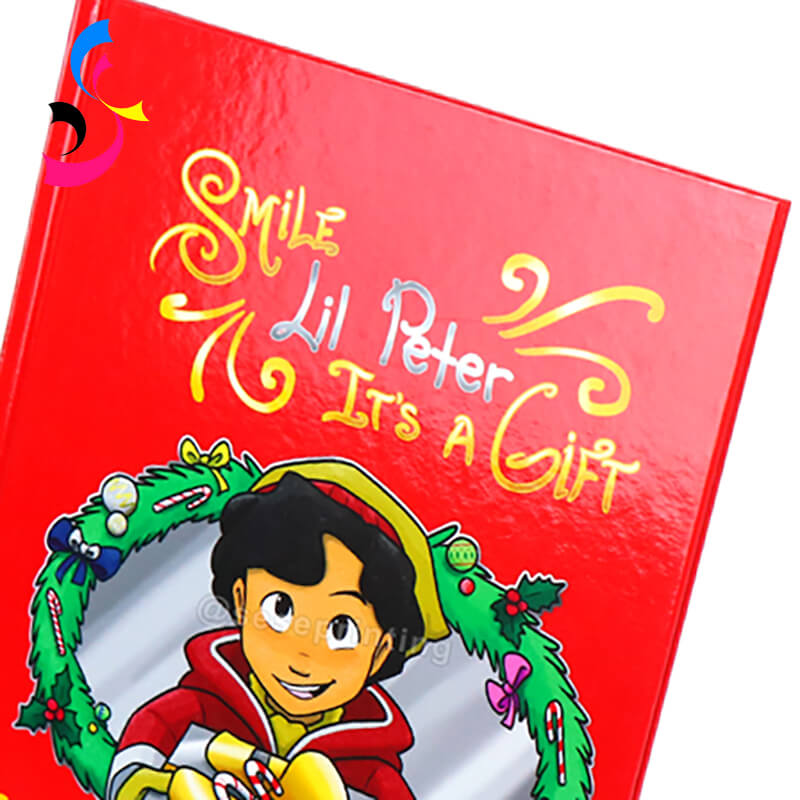

Foil Stamping: This technique uses heat, pressure, and a metallic foil film to create shiny, reflective areas on the cover. It's ideal for titles, logos, and decorative elements. Available in gold, silver, copper, and a spectrum of colored and holographic foils, it instantly adds a touch of luxury and elegance.

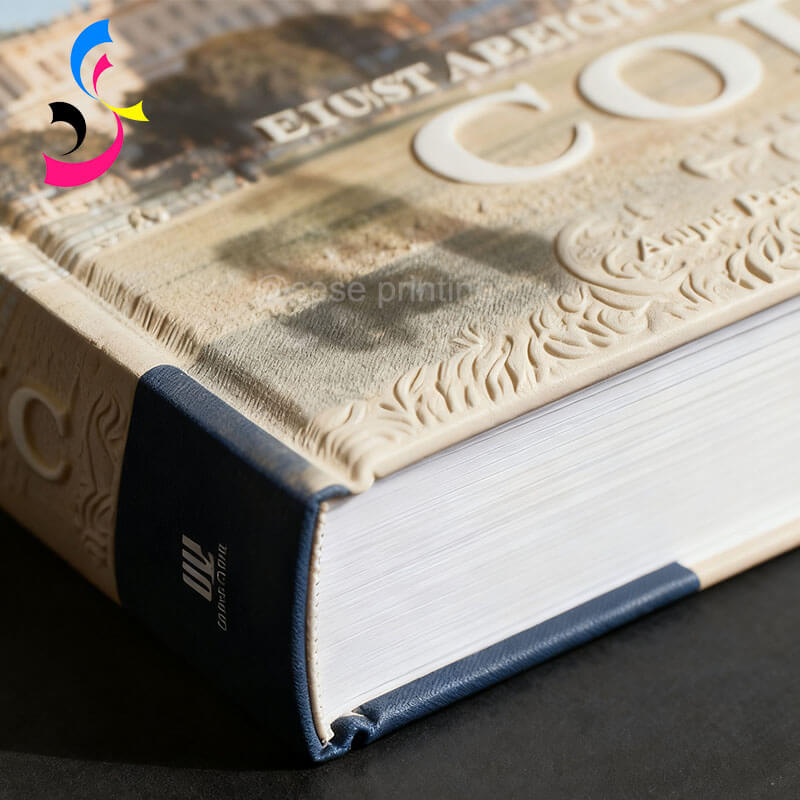

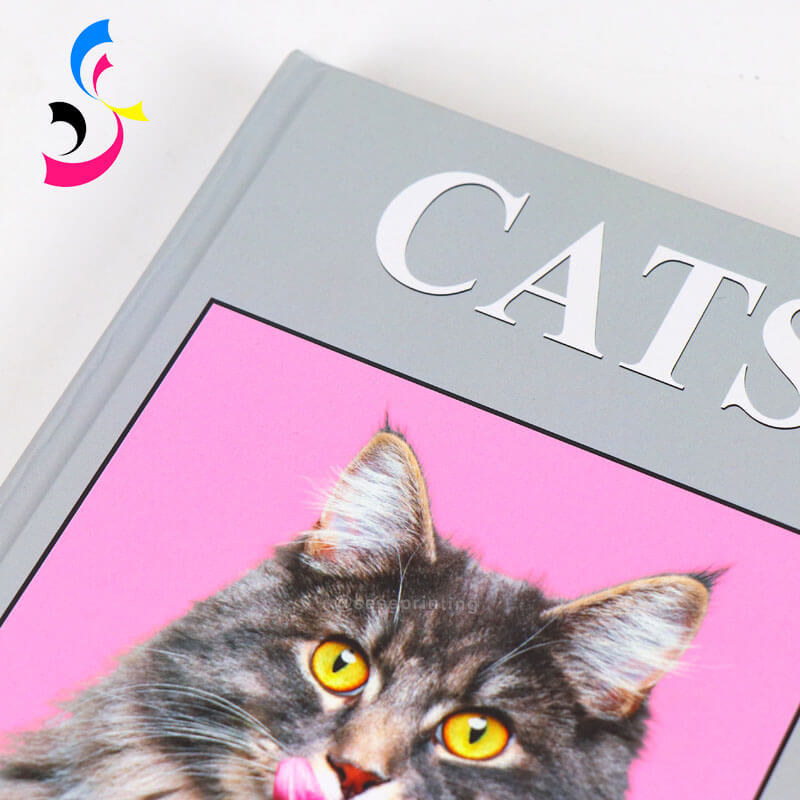

Embossing/Debossing: These are techniques for creating raised (embossing) or recessed (debossing) textures on the cover material. Often combined with foil stamping, embossing adds a sophisticated, tactile dimension that invites touch. "Blind" embossing/debossing (without foil or ink) creates a subtle, elegant effect.

Spot UV Coating: A clear, glossy liquid coating is applied to specific ("spot") areas of the cover. When cured with UV light, it creates a high-gloss, raised finish that contrasts beautifully with matte or uncoated surfaces. This technique is great for making certain design elements, like a title or image, pop.

Screen Printing: A versatile method that lays down a thick layer of ink, resulting in vibrant, opaque colors, especially on darker materials. It's excellent for bold, graphic designs and special inks, such as metallics or glow-in-the-dark. While less common for complex full-color images, it offers a unique, textured feel.

Laminating: This is the process of applying a thin, protective plastic film over the entire printed cover. It comes in two main finishes:

Matte Lamination: Provides a smooth, non-reflective, and sophisticated feel. It is excellent for reducing fingerprints.

Gloss Lamination: Creates a shiny, vibrant surface that makes colors appear richer and more saturated.

Die Cutting: A custom steel die is used to cut out specific shapes or patterns from the cover material. This can create windows that reveal the book's endpaper or elements beneath, adding a layer of intrigue and design complexity.

Soft-touch Matte Lamination: This special type of lamination deserves its own category. It provides a velvety, suede-like finish that is incredibly pleasant to touch. It elevates the perceived quality of the book and offers a unique sensory experience.

3. Custom Printing Techniques for Unique Hardcover Covers

When it comes to customizing hardcover book covers, the possibilities are endless. Authors and publishers can combine various printing techniques to create truly one-of-a-kind designs. Custom features like unique foil patterns, textured covers, or vibrant edge coloring can set a book apart on the shelf. Some other custom options include:

Custom Paper Stocks: Choose specific paper types like linen, fabric, or even leather for a luxurious look and feel.

Sprayed Edges: Color the edges of the book's pages to match or complement the cover design for a cohesive look.

Personalized Covers: Tailor the design with custom artwork or illustrations that reflect the book's content.

Texture Stamping: Similar to embossing, but uses a die to imprint a specific texture (like leather grain, linen, or canvas) onto the cover material.

Foil on Foil: Layering different colored foils to create complex, multi-tonal metallic designs.

Mixed Media Combinations: The most striking covers often combine 3-4 techniques. Imagine a cover with a debossed title, a spot UV coating on a central image, and a soft-touch matte lamination background. The possibilities are endless.

4. Color Printing Techniques: CMYK vs. Pantone

Understanding the difference between CMYK and Pantone colors is essential for achieving the perfect color palette for your hardcover book cover.

CMYK (Cyan, Magenta, Yellow, Black) is a subtractive color model used for full-color printing. It blends these four colors to create a wide range of hues. CMYK is ideal for most standard printing jobs and works well for books that require photographic images or gradients.

Pantone is a standardized color matching system that uses a specific set of colors. Pantone is commonly used for spot colors, particularly for branding elements or metallic hues. If you're looking to create a specific color (such as a unique shade of gold foil), Pantone is the preferred choice.

5. Choosing the Right Techniques for Your Custom Project

Literary Fiction / Memoir: Often benefits from elegant, minimalist designs using blind embossing, foil stamping, and soft-touch lamination.

Fantasy / Sci-Fi: Can handle more complex, full-color artwork with gloss lamination, spot UV, and metallic foils to create a sense of wonder.

Children's Books: Need vibrant, durable covers. Digital or offset printing with a sturdy gloss lamination is a common and effective choice.

Art & Photography Books: Require the highest fidelity color reproduction (often offset printing) and a premium feel, making matte or soft-touch lamination excellent options.

6. How to Work with a Printer

When working with a printer, especially if you're looking for high-quality printing for hardcover book covers, it's important to approach the process with clarity and a good understanding of what you want. Here's a guide on how to work with a printing company, focusing on marketing and effective collaboration.

Research and Choose the Right Printer

Specialization: Make sure the printer you choose has experience with hardcover book covers and offers the specific techniques you're interested in (e.g., foil stamping, embossing, spot UV coating).

Portfolio: Review their past work to see if their style aligns with your vision. Look for quality consistency and attention to detail.

Capabilities: Confirm they can handle the complexity of your design, including custom finishes like gilded edges, embossing, or digital printing.

Initial Consultation

Be Clear About Your Vision: Share your ideas, including design, materials, finishes, and your target audience. The more detailed you are, the better they can understand your needs.

Get Guidance: If you're unsure about the technical aspects, ask the printer for suggestions. Their experience will help guide decisions, especially if you're working with special techniques like embossing or foil stamping.

Understand the Process: Ask about the steps involved, including proofing, production time, and any potential limitations based on your design.

Provide Detailed Specifications

Design Files: Ensure your artwork is in the correct format (usually high-res PDFs) and that the colors are specified in CMYK, which is ideal for printing.

Material Choices: Discuss paper stock options (e.g., glossy, matte, linen) and any custom finishes. These can affect the overall feel and look of the book cover.

Dimensions and Binding: Be precise about the dimensions of the book and how it will be bound (case bound, sewn, etc.). Make sure the printer knows if you need special treatments like dust jackets or slipcases.

Request a Quote

Price Breakdown: Get a detailed quote, breaking down costs for each part of the printing process (setup, materials, printing, finishing).

Minimum Order Quantities: Understand the minimum print runs they require, as this can vary depending on the printer.

Turnaround Time: Confirm the lead time for proofs and final production. Keep in mind that custom finishes might take longer to produce.

Review Proofs Carefully

Digital Proofs: Most printers will provide a digital proof to ensure the layout, design, and text are correct.

Physical Proofs: For custom printing techniques, request a physical proof, especially if you're using special finishes (like foil or embossing). This will give you a feel for the texture and appearance before the full run.

Final Approval: Be meticulous in your review. Double-check all details, from fonts to colors to spacing, as mistakes can be costly and time-consuming to fix later.

Production and Communication

Stay in Touch: Once the job goes into production, maintain communication with the printer to address any potential issues that arise. A good printer will keep you updated on progress and notify you of any complications.

Quality Checks: Ask the printer about their quality control procedures. A reliable printer will perform several checks throughout the production process to ensure consistency and quality.

Flexibility: Be prepared to make last-minute adjustments, especially if issues with proofs arise or if you decide to change something after production begins.

Final Delivery and Post-Production

Inspect the Final Product: When the printed books arrive, carefully inspect the quality of the finish, the binding, and the overall appearance.

Packaging and Shipping: Make sure to discuss how your books will be packaged and shipped. You want to avoid damage during transit, especially if you've chosen a premium finish that could be scratched or dented.

7. Cost Considerations for Custom Printing

Custom printing techniques can add to the overall cost of producing a hardcover book. Factors that influence pricing include:

Quantity: Larger print runs typically reduce the per-unit cost.

Complexity of the Design: Techniques like foil stamping, embossing, or custom die cutting increase the cost due to additional labor and materials.

Type of Paper: Premium or specialty paper stocks will add to the expense.

Finishes: Extra coatings like spot UV, soft-touch matte, or lamination will increase the production cost but offer high-end results.

8. Conclusion

Choosing the right printing techniques for your hardcover book cover is crucial in ensuring its success in a competitive market. At Sese Printing, we specialize in bringing your vision to life with a range of high-quality, custom printing options. Whether you're aiming for the timeless appeal of traditional offset printing or seeking the sophisticated allure of foil stamping and embossing, we offer a variety of techniques that enhance the visual impact and tactile experience of your book.

Our expertise allows us to tailor each project to your specific needs, whether you're publishing a limited edition, a self-published book, or a mass-market title. By working closely with you, we ensure that every detail, from design to finish, reflects your brand and engages your audience. With Sese Printing, you can create a book cover that not only stands out but becomes a memorable visual experience, setting your hardcover book apart in the marketplace.

E-mail: sales01@seseprinting.com

Mobile phone: +86-13570912663

WhatsApp: 008613501482344

Tel: +86-020-34613569

Add: 702 No. 21 Huizhong Road, Shiqiao St, Panyu District. Guangzhou city, Guangdong Province. China