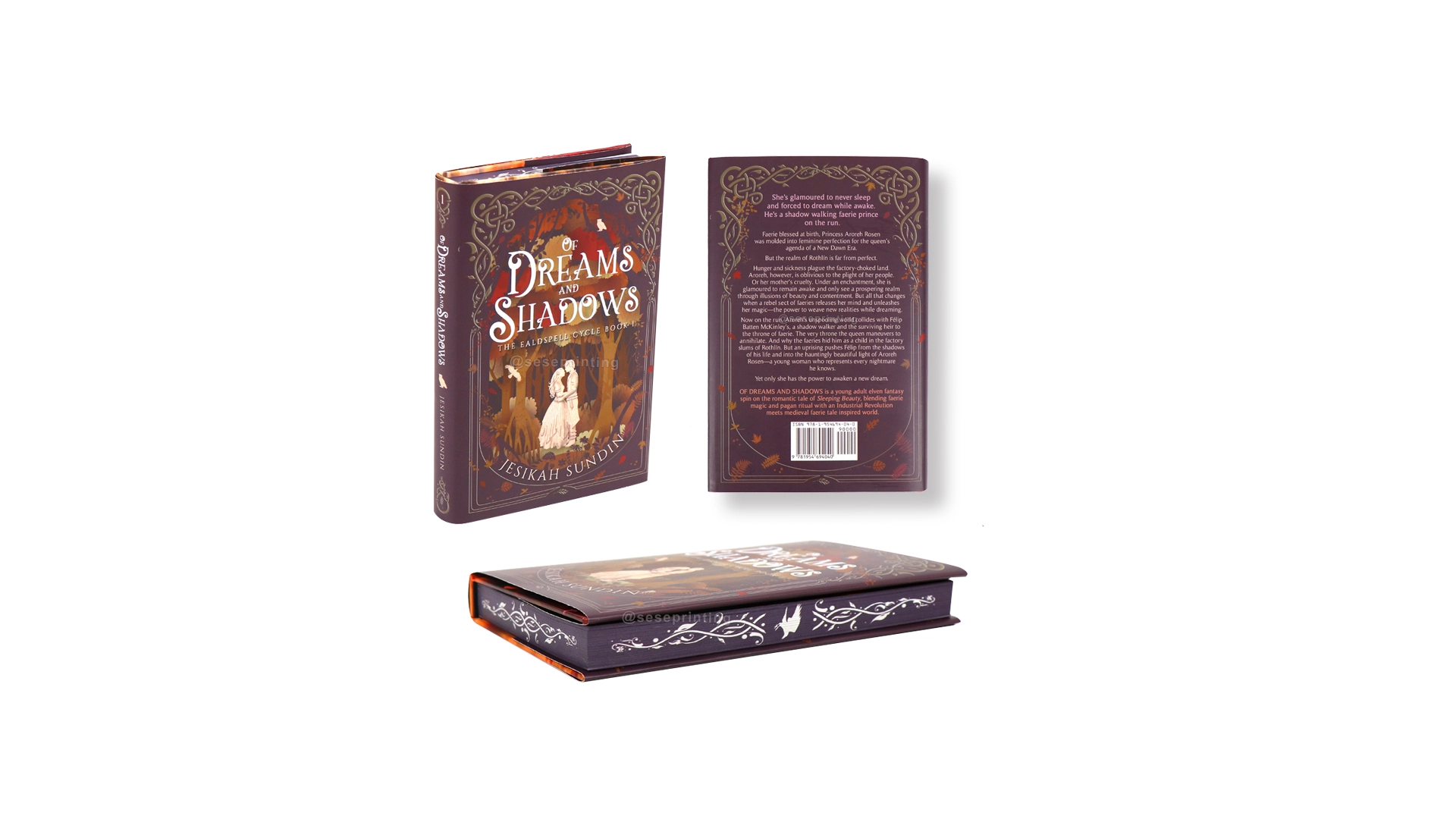

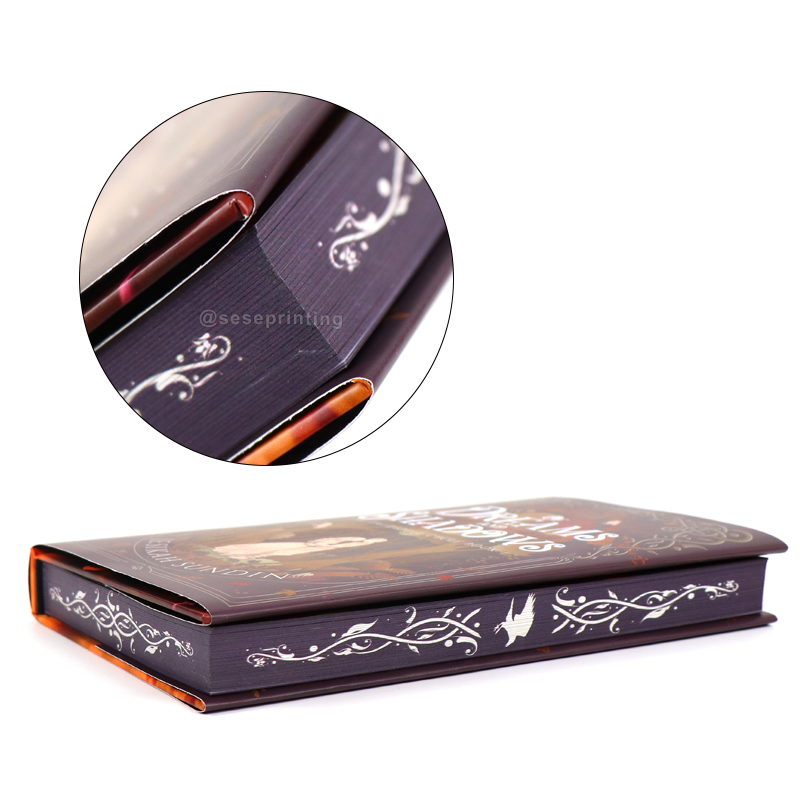

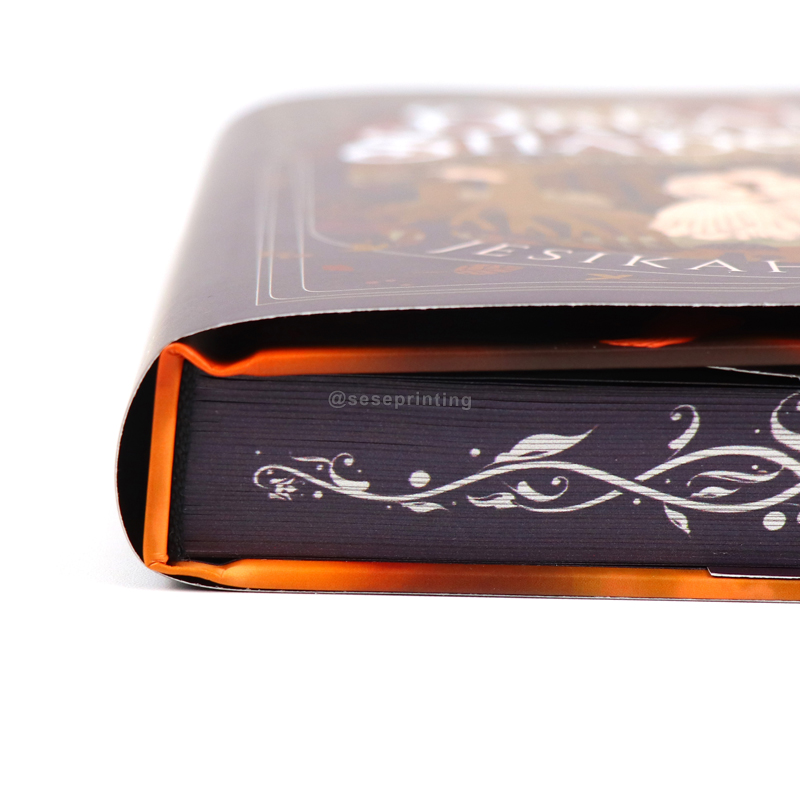

Book Manufacturer Hardcover Sprayed Edges Book with Dust Jacket

Printing a hardcover book with sprayed edges is a popular and visually appealing finishing option that adds a unique touch to the overall design.

Book Manufacturer Hardcover Sprayed Edges Book with Dust Jacket

| Product Name | Hardcover Book with Sprayed Edges | |||

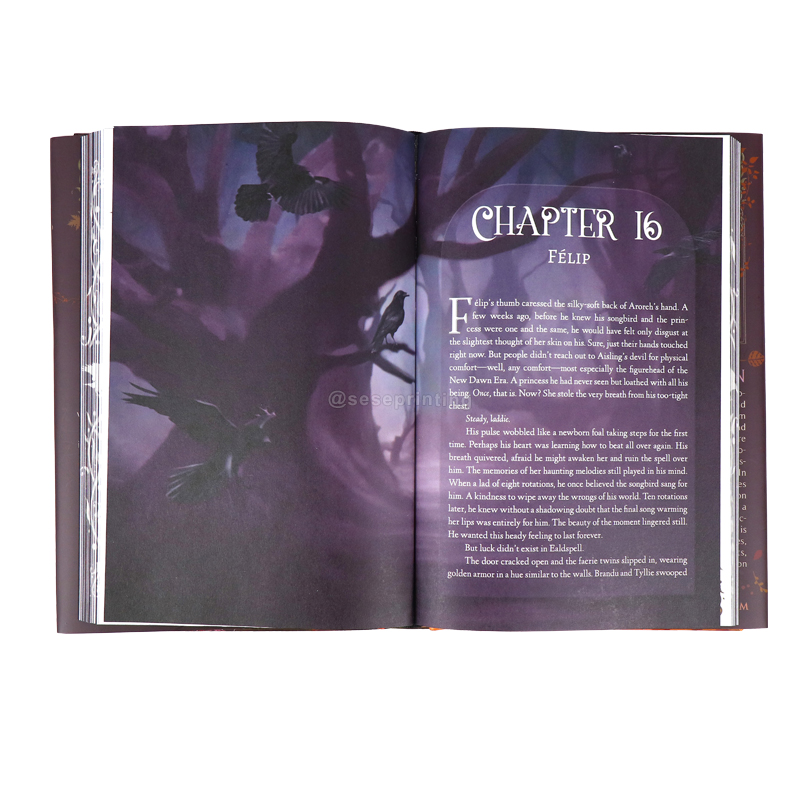

| Material | Glossy/matt art paper, offset paper, woodfree paper, writing paper, light coated paper, special type paper, C1S C2S board,C1S grey board, kraft paper, light weight coated paper, wood free paper, and so on. | |||

| Binding | Thread sewning binding, flexi-bound binding, saddle-stitching binding, glue binding, wire-o binding, spiral binding,casebound binding, etc. | |||

| Certification | ISO9001, FSC | |||

| Design | From Clients,OEM | |||

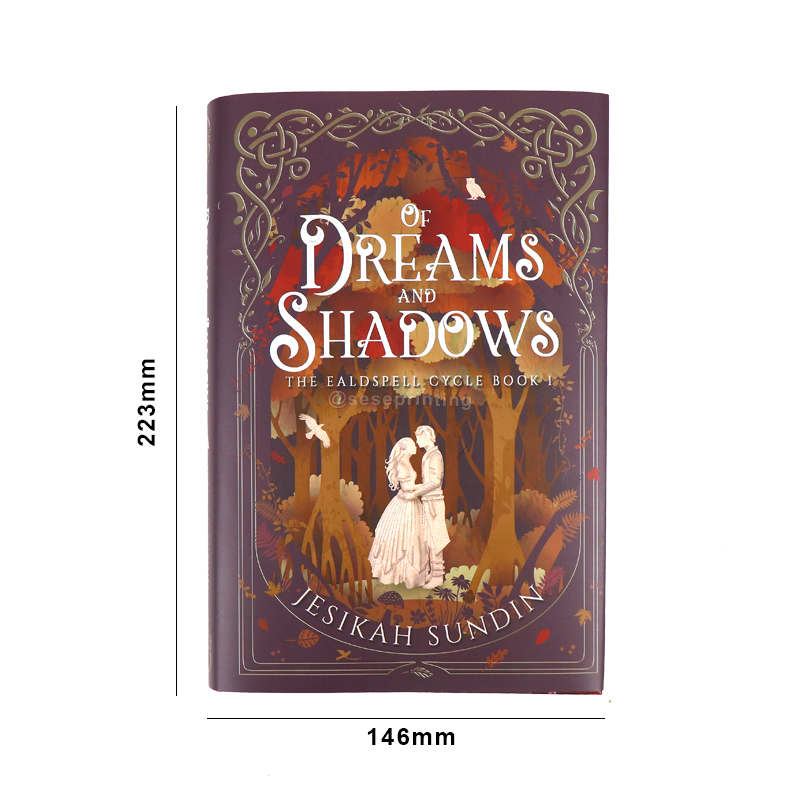

| Size | Decided by Client | |||

| Printing | CMYK or Pantone | |||

| Artwork Format | AI, PDF, ID, PS, CDR | |||

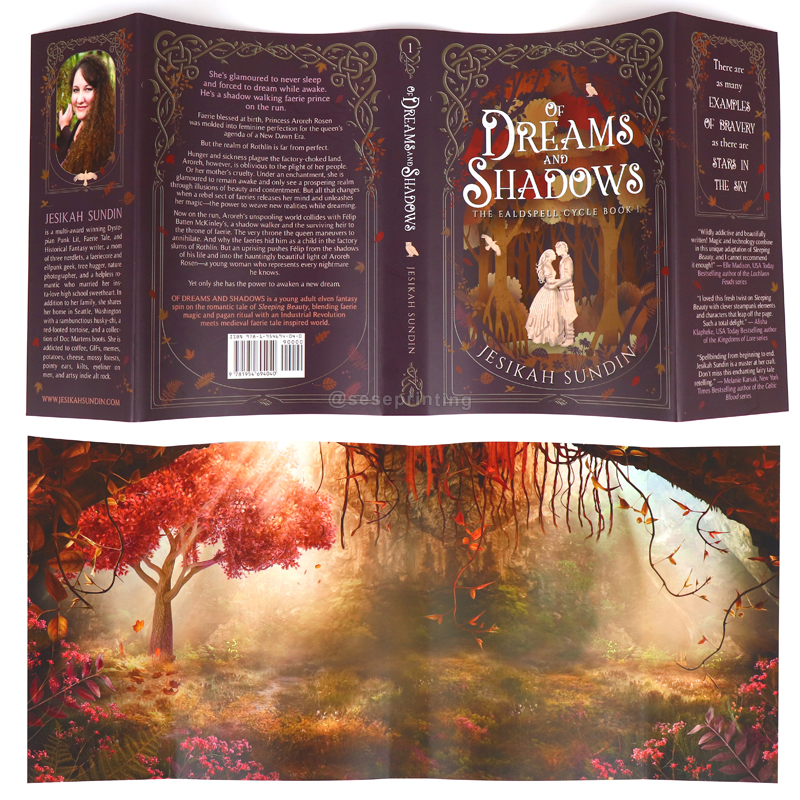

| Finishing | Gloss or Matt Lamination, Spot UV, Emboss, Deboss and Sprayed Edges | |||

The general steps involved in printing a hardcover book with sprayed edges:

Design and Layout:

Work with a graphic designer to create a cohesive design that incorporates the sprayed edges seamlessly with the book cover and interior.

Choose Paper and Colors:

Select the type of paper for the book pages and the cover. The choice of paper can affect the absorption and appearance of the sprayed edges.

Decide on the color or metallic finish for the sprayed edges. Common options include solid colors, metallic gold or silver, or custom colors to match the book's theme.

Prepress Preparation:

Ensure that the design files are prepared according to the printer's specifications, including bleed and trim marks.

Provide specific instructions for the sprayed edges, including the desired color code.

Printing:

The printing process involves applying the ink to the pages and cover of the book. Ensure that the printer is equipped to handle the sprayed edge finishing technique.

Quality control is essential to maintain consistency in color and coverage across all edges.

Spraying Process:

Once the book is printed and bound, the sprayed edges are applied using a spraying machine.

This process requires precision to ensure that the edges are evenly coated without affecting the readability of the text.

Drying:

Allow sufficient time for the sprayed edges to dry completely before handling or packaging the books.

Quality Check:

Perform a final quality check to ensure that the sprayed edges meet the desired specifications and standards.

Binding and Finishing:

Complete any additional binding or finishing processes, such as attaching endpapers, affixing a dust jacket, or adding any embellishments.

Packaging and Shipping:

Package the books securely to prevent damage during shipping.

E-mail: sales01@seseprinting.com

Mobile phone: +86-13570912663

WhatsApp: 008613501482344

Tel: +86-020-34613569

Add: 702 No. 21 Huizhong Road, Shiqiao St, Panyu District. Guangzhou city, Guangdong Province. China