How to Publish a Children's Board Book

How to Publish a Children's Board Book – Focus on Custom Printing

1. Introduction

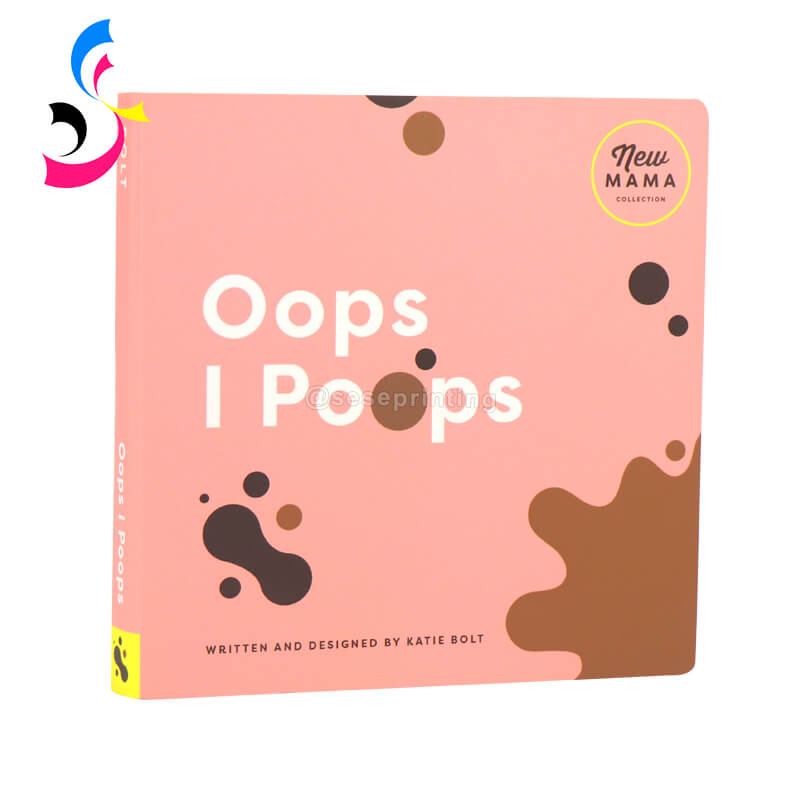

Board books are the sturdy, engaging first books for babies and toddlers, designed to withstand enthusiastic handling, teething, and countless readings. Unlike traditional picture books, they require thick, durable pages and specialized construction. While publishing any book is an achievement, board books present unique challenges and opportunities, especially when leveraging custom printing. This guide focuses on the crucial role of custom printing in bringing your high-quality, unique board book vision to life, ensuring it's safe, durable, and perfectly aligned with your creative goals.

2. Step-by-Step Guide to Publishing

Step 1: Write & Illustrate Your Book

Concept: Develop a simple, engaging story or concept suitable for 0-5 year olds. Focus on repetition, rhythm, bright colors, and familiar objects or experiences.

Text: Keep it minimal. Use clear, large fonts. Rhyming text is popular but not essential.

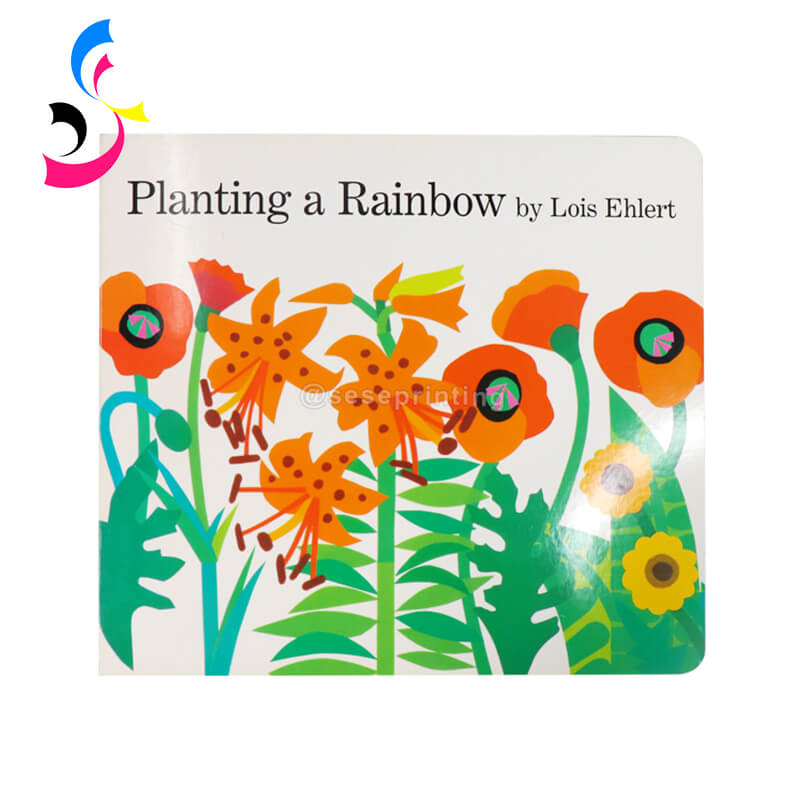

Illustrations: Create bold, high-contrast, colorful artwork. Ensure illustrations are clear and uncluttered. Artwork needs to be high-resolution (usually 300 DPI or higher at final print size).

Safety: Content and design must be age-appropriate. Avoid small detachable parts in the concept.

Step 2: Choose Custom Printing Options (The Heart of Your Board Book)

This is where custom printing shines, allowing you to tailor the book to your exact needs:

Material Selection:

Board Stock Thickness: Choose the right thickness (e.g., 30pt, 35pt) for durability and feel. Custom printers offer various weights.

Board Type: Standard whiteboard, greyboard, or specialty options like eco-friendly recycled board.

Coating: Essential for wipeability and durability. Options include Matte Laminate (popular, reduces glare, soft feel), Gloss Laminate (vibrant colors, shiny), or Spot UV (for specific raised/shiny effects).

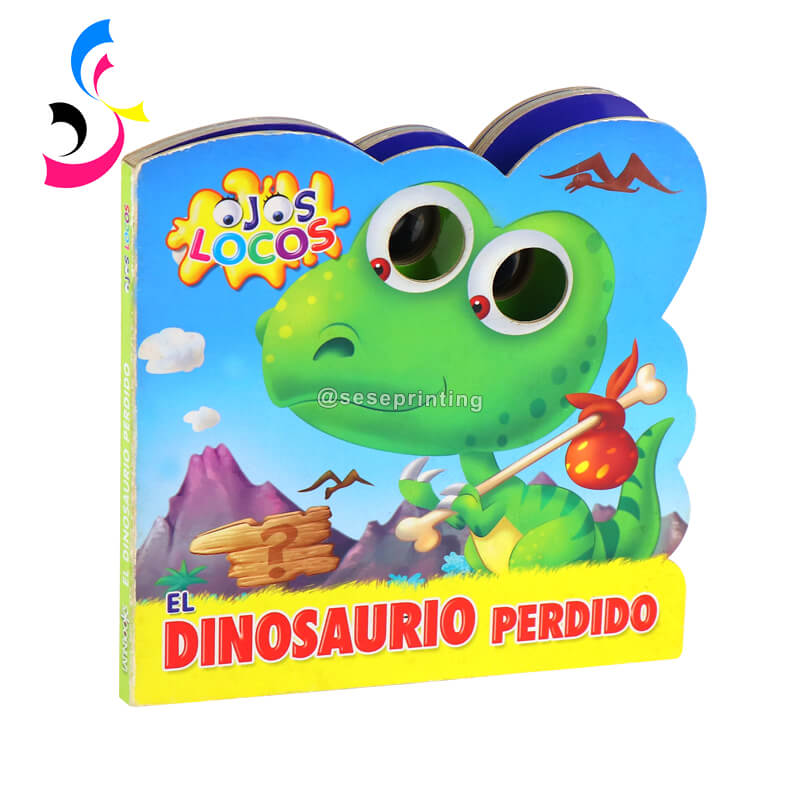

Size & Shape: Standard sizes exist (e.g., 5"x5", 6"x6", 7"x7"), but custom printing allows unique shapes (die-cutting – circles, animals, objects) and non-standard sizes to make your book stand out.

Page Count: Board books typically have 10-20 pages (5-10 spreads) due to binding constraints. Custom printers can advise on feasible counts for your chosen binding.

Binding: Board Book Binding is specialized: layers of board are glued together at the spine edge. Ensure your printer specializes in this. Rounded corners are standard for safety.

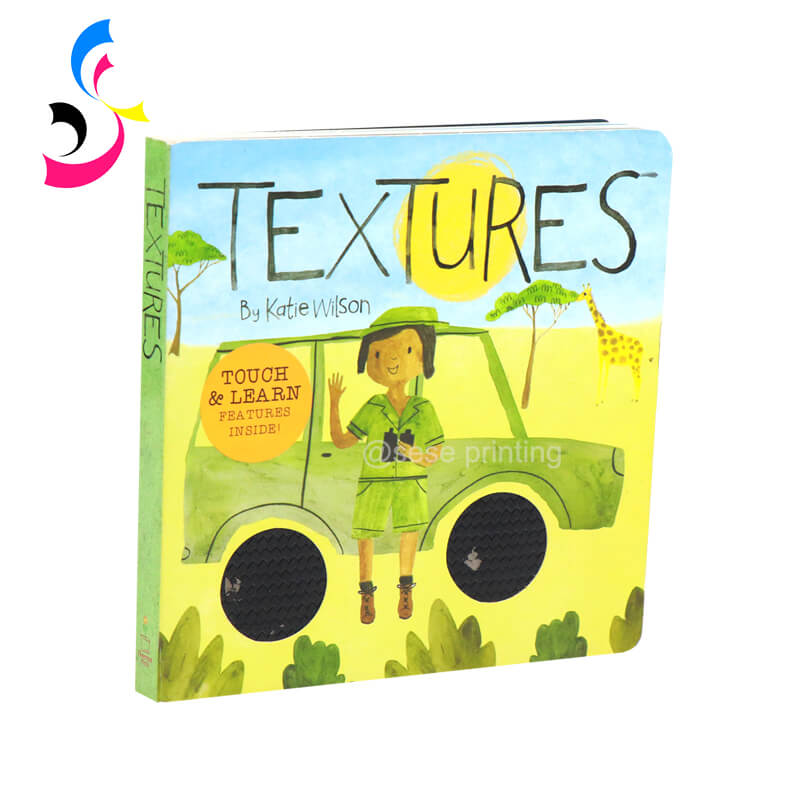

Special Effects: Explore custom options like:

Die-Cutting: Holes or shaped pages.

Foil Stamping: Metallic accents on cover or pages.

Embossing/Debossing: Raised or recessed textures.

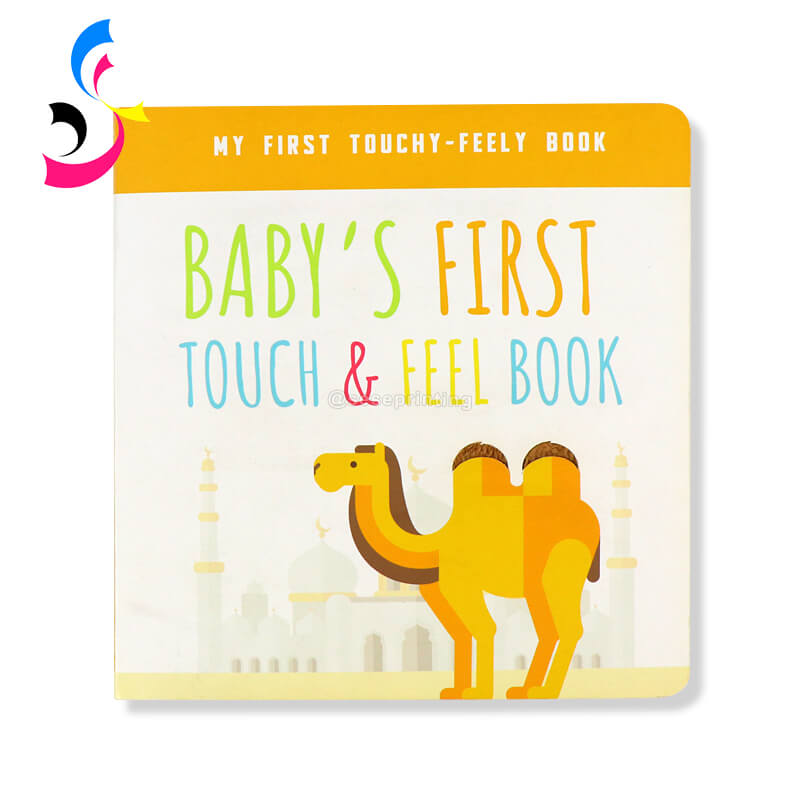

Touch-and-Feel Elements: Adding different textures (felt, fur, bumpy plastic) – requires careful planning and safety testing.

Lift-the-Flap Pages: Interactive elements where readers lift sturdy flaps to reveal concealed images or text beneath.

Safety Certification: Crucial! Ensure your chosen materials and printing processes meet international safety standards for children's products (e.g., ASTM F963, EN71). Your printer should provide documentation (like a Children's Product Certificate - CPC if selling in the US).

Step 3: Select a Printing Partner

Choosing the right printer is paramount for a successful board book. Look for partners with:

Specific Expertise: Proven experience in children's board book printing.

Customization Capabilities: Ability to handle your desired materials, effects, and binding.

Quality Control: Rigorous checks for color accuracy, binding strength, and material defects.

Safety Compliance: Clear understanding and provision of necessary safety testing documentation.

Communication & Support: Responsive customer service to guide you through the process.

Minimum Order Quantities (MOQs): Realistic MOQs for self-publishers (often starting around 500-1000 copies).

Samples: Always request physical samples of their board book work.

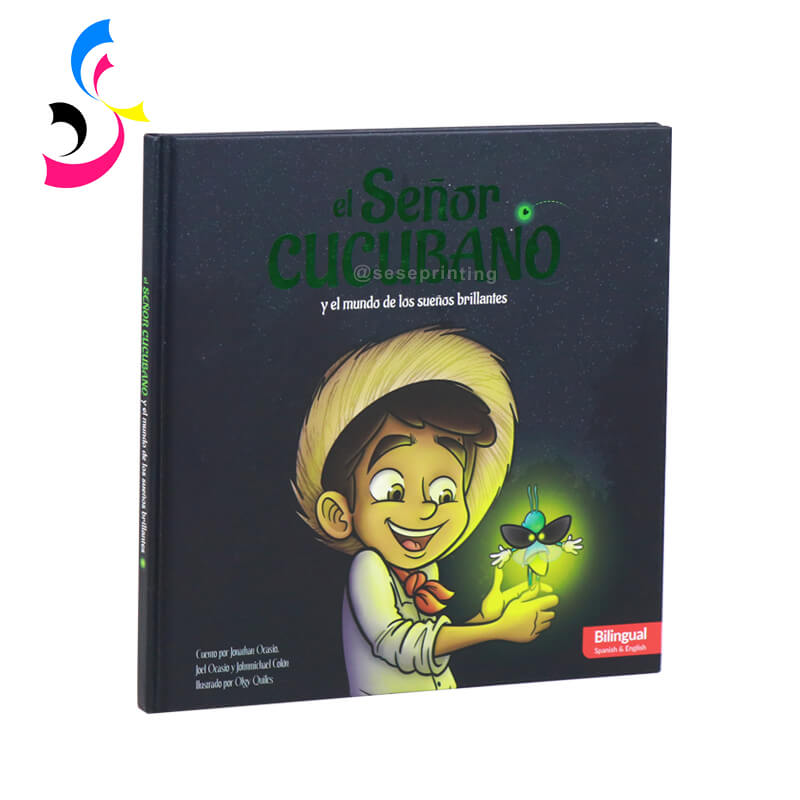

Example Partner: Sese Printing is a notable example of a printer specializing in custom children's books, including board books. They often offer comprehensive services from printing to binding, various customization options, competitive MOQs, and emphasize safety compliance – making them a strong contender to evaluate for your project. (Get quotes from several specialized printers).

Step 4: Format for Printing

Bleed & Trim: Artwork must extend beyond the final trim edge (usually 3mm/0.125" bleed) to avoid white borders after cutting.

Safety Margins: Keep critical text and artwork away from the trim edges and spine (usually 5-10mm inside).

File Format: Provide print-ready PDFs in CMYK color mode, high resolution (300+ DPI), with all fonts embedded or outlined.

Spreads: Layout the artwork as spreads (two facing pages together).

Printer Templates: Use the printer's specific templates and guidelines for page size, bleeds, and margins. Communicate clearly about any die-lines or special effects.

Step 5: Publish & Distribute

Order a Proof: Always request a physical proof before the full print run to check colors, binding, and finish.

Print Run: Approve the proof and proceed with your initial print quantity.

Distribution Channels:

Direct Sales: Your website, farmers markets, craft fairs, author events.

Online Retailers: Amazon KDP (Note: KDP does not offer true board book printing, only a thicker paperback), Etsy, eBay.

Bookstores & Boutiques: Approach local independent stores or children's boutiques (often on consignment).

Libraries & Schools: Donate copies or offer author visits.

Wholesalers: Use distributors like IngramSpark (who can connect with bookstores, libraries, and online retailers globally - ensure your printer provides files compatible with their requirements if needed).

3. Why Custom Printing?

Unmatched Quality & Durability: Control the materials to ensure your book withstands rough toddler handling, drool, and repeated use. Standard printing often can't match this.

Unique Brand Identity: Stand out on crowded shelves with custom shapes, sizes, special finishes (foil, UV, texture), and unique binding options.

Creative Freedom: Realize your exact vision, whether it's intricate die-cuts, specific textures, or non-standard dimensions. Mass-market options are very limited.

Safety Assurance: Work directly with printers who understand and prioritize the stringent safety requirements for children's products and provide necessary documentation.

Control & Flexibility: Set your own print quantities (within MOQs), manage inventory, and make iterative improvements between print runs.

Higher Per-Book Profit Potential: While the upfront cost per book is higher than mass-market paperback printing, you can command a higher retail price point for a premium, custom product.

4. Tips for Success

Start Simple: For your first book, consider limiting complex (and costly) special effects. Focus on great content, sturdy construction, and vibrant printing.

Budget Realistically: Custom board books have significant upfront costs (illustration, design, safety testing, printing). Factor in all expenses (printing, shipping, warehousing, marketing).

Safety is Non-Negotiable: Never cut corners on safety testing or material compliance. Use only printers experienced in children's products.

Invest in Professional Design: Layout for board books requires specific knowledge (bleed, safety margins, spread design). Hire a designer experienced in children's books and print production if needed.

Get Physical Samples: Before committing to a large print run, order samples from potential printers to assess quality, feel, and durability firsthand.

Understand MOQs: Be prepared for minimum order quantities typically starting at 500-1000 copies for cost-effectiveness. Have a storage and distribution plan.

Market Early: Build an audience before your book launches through social media, author websites, and local networks.

Consider Distribution Logistics: How will you store and ship heavy board books? Factor these costs into your pricing.

5. Conclusion

Publishing a children's board book is a rewarding endeavor, creating a tangible product that can spark early literacy and joy. While it demands careful planning and investment, focusing on custom printing is the key to producing a book that is not only beautiful and engaging but also exceptionally durable and safe for little hands. By understanding the unique requirements of board book production, carefully selecting an expert printing partner like Sese Printing or similar specialists, and leveraging the power of customization, you can transform your story and illustrations into a high-quality, standout book that families will treasure for years to come. Embrace the custom process – it's your path to creating a truly special board book.

E-mail: sales01@seseprinting.com

Mobile phone: +86-13570912663

WhatsApp: 008613501482344

Tel: +86-020-34613569

Add: 702 No. 21 Huizhong Road, Shiqiao St, Panyu District. Guangzhou city, Guangdong Province. China