Selecting the Right Material and Surface Option for Your Paper Box

Selecting the Right Material and Surface Option for Your Paper Box

1. Introduction

In today's competitive market, a product's packaging is often the first physical interaction a customer has with your brand. It's a powerful silent salesman, communicating your values, quality, and attention to detail before the box is even opened. Beyond mere protection, custom paper boxes are a crucial marketing tool. The choice of material and surface finish is paramount in crafting this first impression. Selecting the right combination ensures your box not only looks stunning but also feels premium, resonates with your target audience, and perfectly encapsulates your brand's identity. This guide will walk you through the key options and considerations to make an informed decision.

2. Popular Materials for Custom Paper Boxes

Kraft Paper: Kraft paper is a sustainable and eco-friendly choice, widely used for natural, organic, or eco-conscious brands. It has a raw, earthy texture and is highly durable, making it perfect for shipping boxes, retail packaging, and brands that want to highlight their commitment to sustainability.

Duplex Board: Duplex board offers excellent strength and printability. It is commonly used for custom retail boxes and product packaging that require vibrant designs while maintaining structural integrity.

White Cardboard (C1S/C2S): White cardboard is smooth and provides excellent printing quality. C1S (coated one side) and C2S (coated both sides) allow for vivid graphics and high-end finishes. It’s suitable for cosmetic boxes, electronic product packaging, and premium retail boxes.

Rigid Paperboard: Rigid paperboard, also known as chipboard, is thicker and more durable, often used for luxury packaging such as jewelry boxes, gift boxes, and high-end consumer goods. It adds a sense of sophistication and premium value.

Corrugated Board: Corrugated board is ideal for shipping and heavy-duty packaging. It combines durability with cushioning properties, ensuring product safety during transport while still allowing for branded printing.

3. Surface Options and Finishes

Gloss and Matte Lamination: Lamination protects the surface of the box and enhances its look. Gloss lamination offers a shiny, vibrant finish, while matte lamination provides a soft, elegant feel.

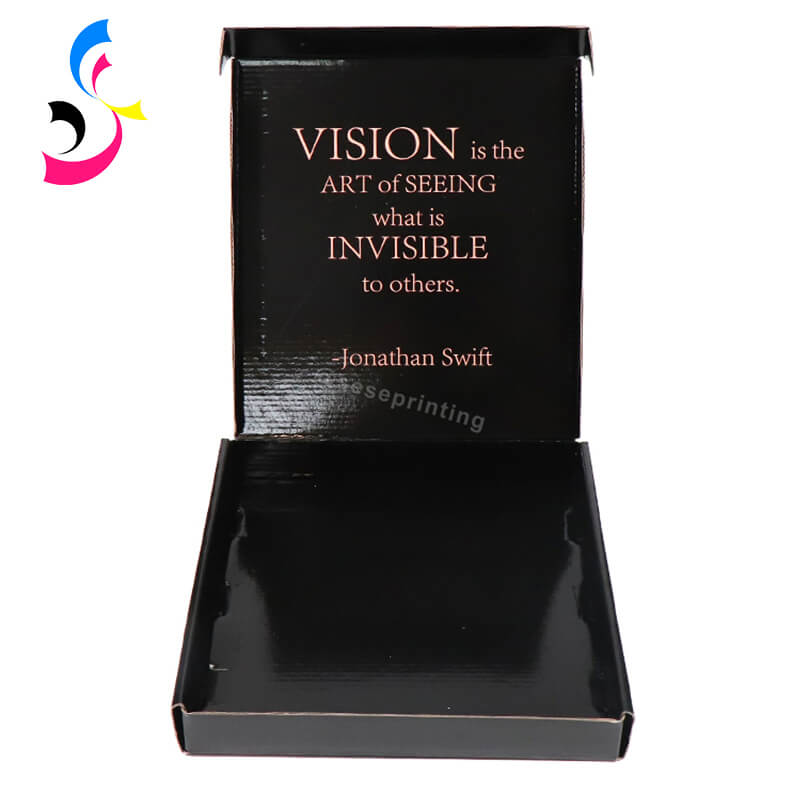

Spot UV Coating: Spot UV applies a glossy highlight to specific areas such as logos or patterns, creating a striking contrast with matte backgrounds. It's a popular option for luxury and modern designs.

Foil Stamping: Foil stamping in gold, silver, or holographic tones adds luxury and eye-catching appeal. Perfect for brands aiming for elegance, sophistication, and exclusivity.

Embossing and Debossing: Embossing raises designs above the surface, while debossing presses them into the material. Both techniques enhance the tactile quality of the box and emphasize logos or brand elements.

Soft-Touch Coating: Soft-touch provides a velvety finish, creating a premium feel. It's especially popular for cosmetic packaging and high-end electronics.

Die-Cutting: Using a custom-shaped blade to cut out parts of the box material. This allows for unique window patterns, revealing the product inside, or creating innovative structural designs that enhance brand recognition.

4. How to Match Material & Surface with Your Brand

Brand Personality: Is your brand modern and bold? SBS with Gloss Lamination and vibrant printing might be perfect. Is it rustic and authentic? Kraft or Recycled board with a simple AQ coating could be ideal. Is it luxury and elegant? SBS with Matte Laminate, Foil Stamping, and Embossing will convey that premium feel.

Target Audience: Understand what resonates with your customers. A younger demographic might appreciate bold colors and unique die-cuts, while a high-end clientele will value subtle textures and metallic finishes.

Product Value: The packaging should match the product's price point. A high-value item deserves premium materials and finishes to justify its cost and enhance the unboxing experience.

Functionality: Always consider durability needs. A shipping box requires sturdy corrugated material, while a gift box might prioritize aesthetics with a delicate paperboard.

5. Find a Custom Paper Box Manufacturer

Navigating the myriad of options for materials and finishes requires an expert partner. This is where choosing the right manufacturer becomes critical. Sese Printing stands out as a premier provider of custom paper box solutions.

With years of expertise and a commitment to quality, Sese Printing offers end-to-end service—from conceptual design and material selection to precision printing, finishing, and assembly. We work closely with our clients to understand their brand vision and recommend the perfect material and surface finish combination that aligns with their goals and budget.

Our state-of-the-art facilities support all the advanced techniques discussed, including high-definition offset printing, intricate foil stamping, embossing, and a variety of lamination options. At Sese Printing, we don't just manufacture boxes; we help you create unforgettable brand experiences.

Ready to create stunning custom paper boxes that wow your customers? Contact us today for a consultation and quote. From small custom runs to large-scale production, our team offers professional guidance to help you choose the most suitable material and finish for your packaging.

6. Conclusion

The material and surface finish of your paper box play a vital role in shaping the customer experience. Whether your brand emphasizes sustainability, luxury, or bold shelf presence, the right combination will elevate your packaging and strengthen your brand image. By understanding the strengths of different materials and finishes—and partnering with a trusted manufacturer like Sese Printing—you can create custom paper boxes that deliver both function and unforgettable style.

E-mail: sales01@seseprinting.com

Mobile phone: +86-13570912663

WhatsApp: 008613501482344

Tel: +86-020-34613569

Add: 702 No. 21 Huizhong Road, Shiqiao St, Panyu District. Guangzhou city, Guangdong Province. China